Functional description and benefits

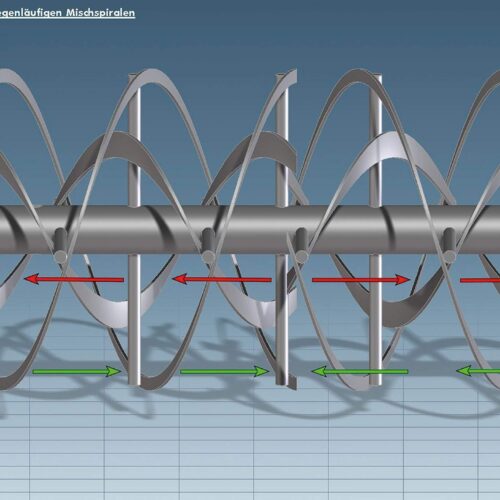

Vertical and horizontal ribbon blenders achieve an excellent mixing accuracy and minimum particle degradation by means of helical spiral-ribbons creating a three-dimensional “cross-flow” inside the mixer.

The helical spiral positioned in the center of the horizontal blender transports the material in the opposite direction to the outer spiral transporting the peripheral material. When the mixing process is finished, the homogeneous product is discharged from the mixing chamber through the outlet ports.

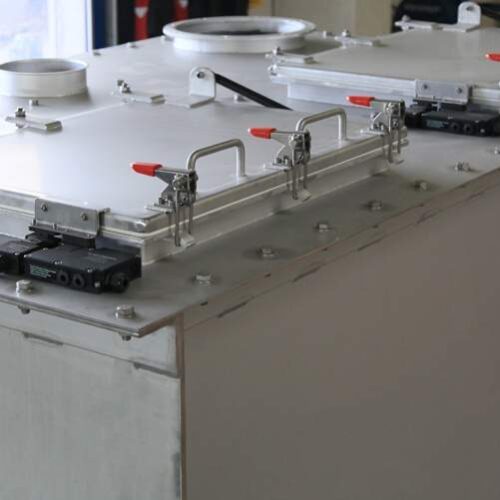

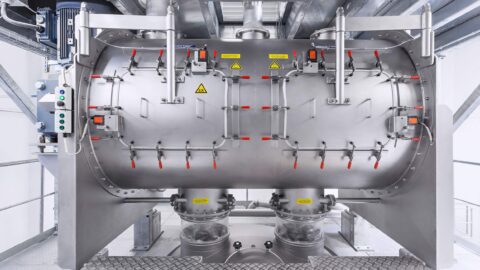

The optional jacketed housing design makes these blenders ideal to be used as an indirect heat exchanger (heating, cooling, drying). Large cleaning doors allow for quick and easy access for cleaning and inspection.

According to the requirements of the mixing process’ respective product characteristics, you can choose between a vertical or horizontal ribbon blender.

All blenders are in compliance with FDA regulations and meet high-end sanitary standards and pharmaceutical requirements.

Advantages

Customized design

Mixing accuracy of 1:100 000 and larger

Gentle mixing assuring minimum particle degradation

Jacketed housing for indirect heat exchange

Large doors for cleaning & inspection

Vacuum-rated design

Usable for dry powders, pastes, doughs & wet components

High-end surface finish

Robust design

Hygienic Design

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.