Functional description and benefits

Vertical ribbon blenders deliver a high mixing accuracy within a very short time. Sophisticated mixing operations can be carried out for products with many different characteristics (densities, granulation, heat sensitive, pressure sensitive and hydroscopic).

The material enters the mixing chamber through a suitably-sized inlet and is simultaneously distributed by the mixing tool. The mixer shaft is suspended and supported from the drive shaft. The mixing action is – product is transported up the wall of the mixer then cascaded down the center. The complete content is kept in constant motion, there are no dead zones. Even with batches as low as approx. 10 percent of the capacity, an optimal mixing quality is still achieved.

The variable speed drive allows for gentle mixing. The use of the high speed cutter rotors enables high intensity mixing and to add inclusions such as liquids, flakes or block fats.

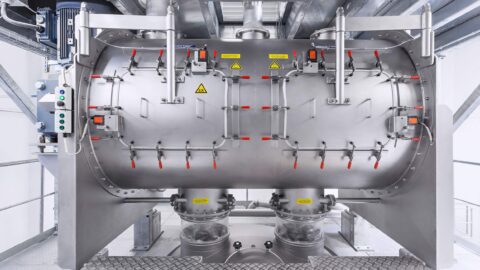

The system is designed with a large inspection door for necessary inspections, easy cleaning by hand, automatic cleaning in place (CIP) and disinfection. The inside of the mixer is covered with a non-stick coating. Additional sockets for venting, inspection hatch and additional intake positions are considered during the design process. The mixer is discharged at the bottom by means of a rotating arm which covers the complete bottom of the mixer, and direct the product to the outlet port.

Advantages

Customized design

Mixing precision of min. 1:100.000 and higher for variable batches, even as low as 10 percent of the capacity

Fast mixing process

Designed to be tempered for product heating & drying

Large doors for cleaning & inspection

Offers automatic cleaning in place (CIP) and disinfection

Vacuum rated design

For dry powders, pastes, doughs & liquid inclusions

Robust design

Hygienic Design

Optional dust explosion rated (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.