Functional principle and benefits

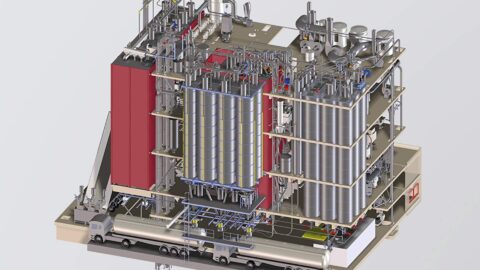

State-of-the-art truck loading silo systems, used in flour production facilities for instance, ensure extremely high loading speeds by utilizing dust proof, pneumatic loading spouts. They are equipped with automated truck weighing & feed controls systems including visualization.

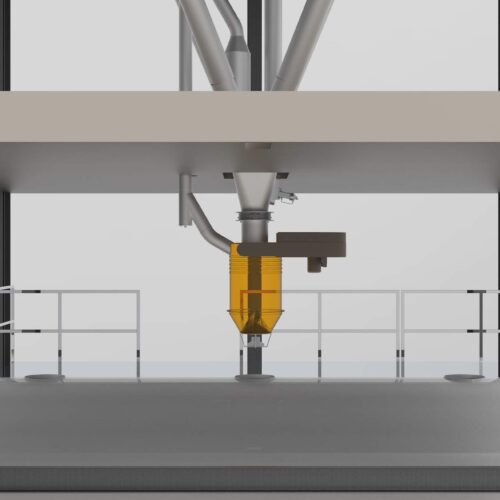

The truck enters the door of the loading facility and is typically positioned on a built-in floor scale. The truck can be weighed either by the built-in floor-scale, or the weight of the silo cells themselves can be monitored for controlling the discharged quantity. When the truck reaches the desired loading spout position, the loading spout is pressed onto the trucks filling gate pneumatically and minimizes dust leakage and large truck-loading flow rates. For instance, 25 tons of flour can be loaded within five minutes.

The complete loading takes place in a fully enclosed loading hall. In order to avoid condensation, the complete hall can be equipped with isolating sandwich-panels.

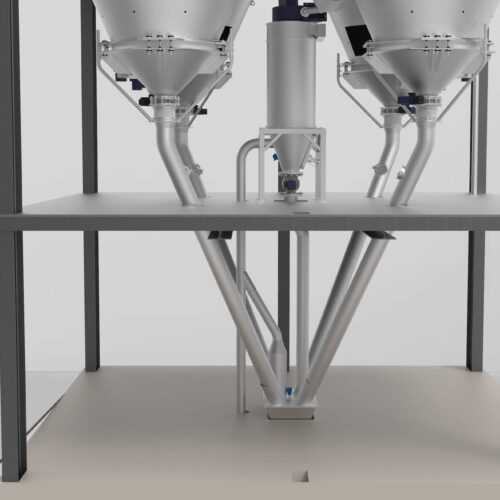

Silos are typically equipped with bin vent filters (jet filter), burst discs (dust explosions), pressure relief valves, level limit switches, discharge devices etc. The silo discharge device must be carefully suited to the application at hand in order to ensure the flawless function of the system. Typical selections would be a vibro-bin discharger or a fluid bed discharger depending on the material properties.

HACCP requirements and IFS Standards are met. Exact traceability and EAN coding is assured.

Advantages

Custom turnkey system solutions

Efficient space utilization through custom design

Complete turnkey design, fabrication & installation

Reliable silo discharge systems tailore to the desired application

Large truck-loading flow rates, up to 300 tons/h

Optional pneumatic loading spouts with minimal dust leakage

State-of-the-art discharge weight control systems

Fully enclosed, contamination-free truck loading facilities

Complete product traceability

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.