Sourdough and wheat pre-dough give baked goods a unique flavor. These products excel with a longer shelf life and improved aroma. Improved yield and increased quality, resulting in the reduction of bakery ingredients with a flexible production and catering to individual customer needs.

Description

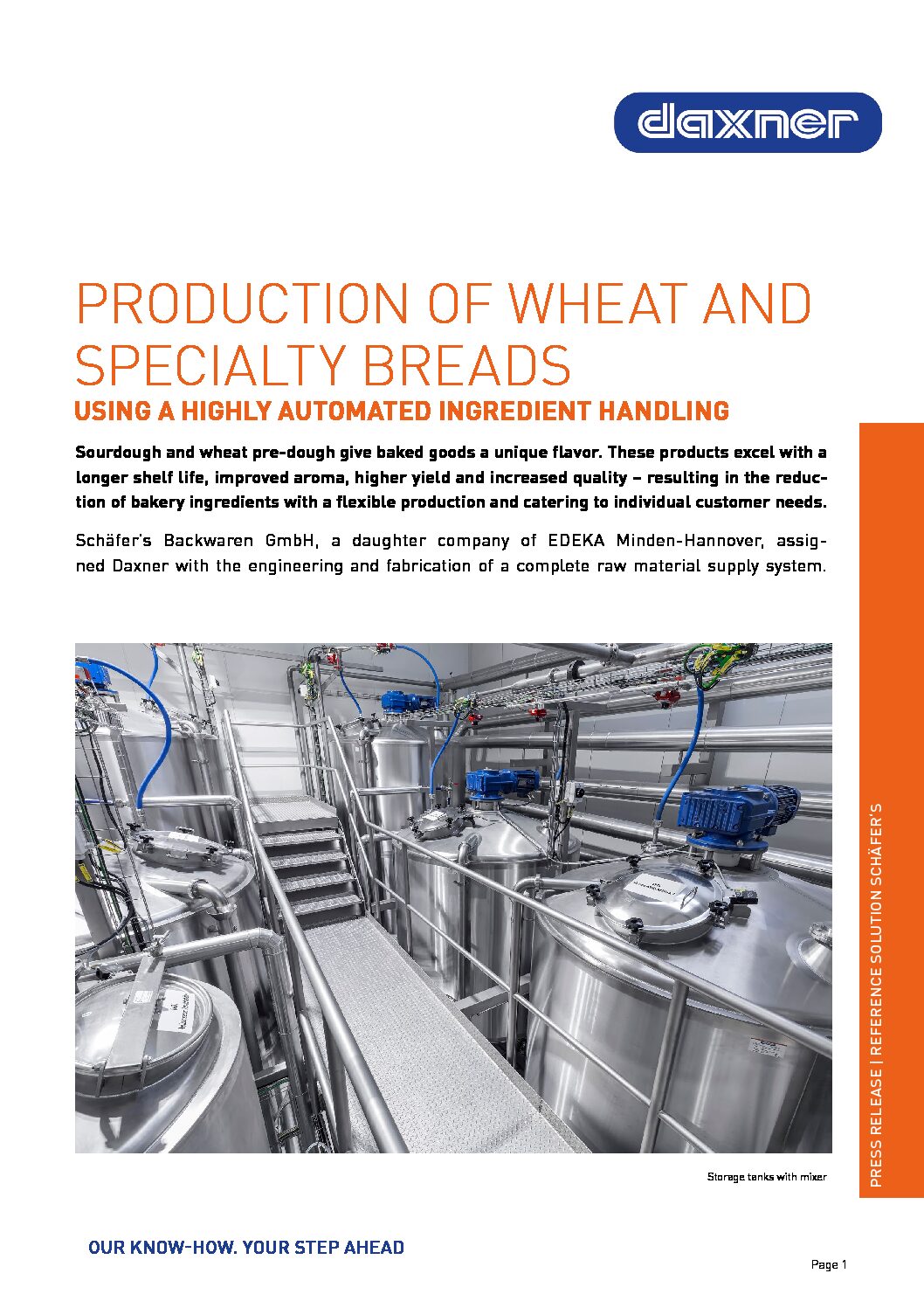

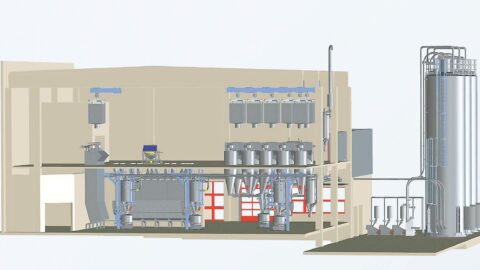

Schäfer’s Backwaren GmbH, a daughter company of EDEKA Minden-Hannover, assigned Daxner with the engineering and fabrication of a complete raw material supply system.

The facility in Osterweddingen is Schäfer’s state-of-the-art production site and belongs to the most innovative producers of frozen baked goods in Germany. Currently, around 220 employees on four highly industrialized production lines produce bread rolls, croissants and Danish pastries.

The centralized plant control system enables complete process visualization and monitoring, starting from the raw material supply up to the packaging lines. Touch panels throughout the system enable operating the various processing machines locally.

Efficient raw material handling

Silo trucks fill the six outdoor silos and two indoor silos pneumatically. Meanwhile, the salt brine and component silos are filled over assigned inlets, which are suitable for sacks and Big bags.

The ingredients for each recipe are delivered directly above the kneaders. A pneumatic vacuum conveyor, supplying the ingredients from the silos fills the containers positioned above the kneaders.

The weighing of the recipe components takes place in the small weighing stations below the silos. To guarantee consistent product quality, the ingredients are weighed once more on each of the production lines.

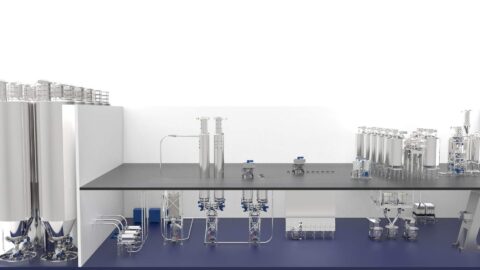

Automated wheat sponge and sourdough production with continuous mixer and pipe “pig” cleaning system

To produce wheat sourdough or wheat sponge, the flour is conveyed from the raw material system to a receiver bin. Using the loss-in-weight feeder, a constant supply of material is guaranteed to the continuous mixer.

To produce a homogenous mass, the liquid components of the wheat pre-dough are conveyed to the continuous mixer via connection lines. By means of a time and temperature controlled system, the mixer can be operated directly at the station or via a computer in the production office.

Intelligent soaking system with preparation tank, storage tanks and pipe “pig” cleaning system

The liquid components of the soakers are heated up to the desired temperature by a water mixing system and reach the preparation tank through a pipe system. Afterwards, the loading cells transport seeds and grains to the swelling tanks. The time-controlled system can be operated centrally in the production office.

Furthermore, Daxner integrated an inline seeds and grains sprinkler unit.

Salt brine preparation

The salt brine system daxSol was designed for the production of cold dough. The automated addition of salt brine meets the highest hygienic standards in dough preparation.

A product intake station followed by a screw conveyor fills the salt brine system. To ensure highest product quality, the pneumatic conveying lines are equipped with inline screening machines and metal separators whilst the intake station also has sieves and metal separators. The salt is dosed into a water-filled preparation tank where the solution cools down. The chilled salt brine is stored in a storage tank and is added as required to the mixture. An intermediate pumping process ensures the stability of the solution.

A sub-divider distributes the on-site chilled water around three chilled water rings for the soaker, the sourdough, the sponge and the salt brine.

FIBC tandem station for the automatic supply with edible oils

To guarantee the constant oil supply, Schäfer’s went with a two-container system. Once the first container is empty, the second, full container is available for the production process. In the meantime, the empty container is removed by a forklift and substituted with another full container without hindering the dosing process of the other FIBC.

Easy and fast cleaning with an integrated CIP system

The integrated CIP system ensures food safety, minimizing downtime and reducing personnel for the cleaning process.

The processing plants connected to the CIP system for wheat sponge and soakers clean themselves automatically in-between production cycles. This minimizes potential contaminations and quality defects even further. The piping system is kept clean via a pig cleaning system; product residue is washed out through pipes into the drainage system.

The state-of-the-art production plant near Magdeburg is one of the most efficient, reliable factories in the German baking industry. With its fresh, high-quality and first-class ingredients, traditional recipes and modern manufacturing processes are combined.

Key components

of this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.