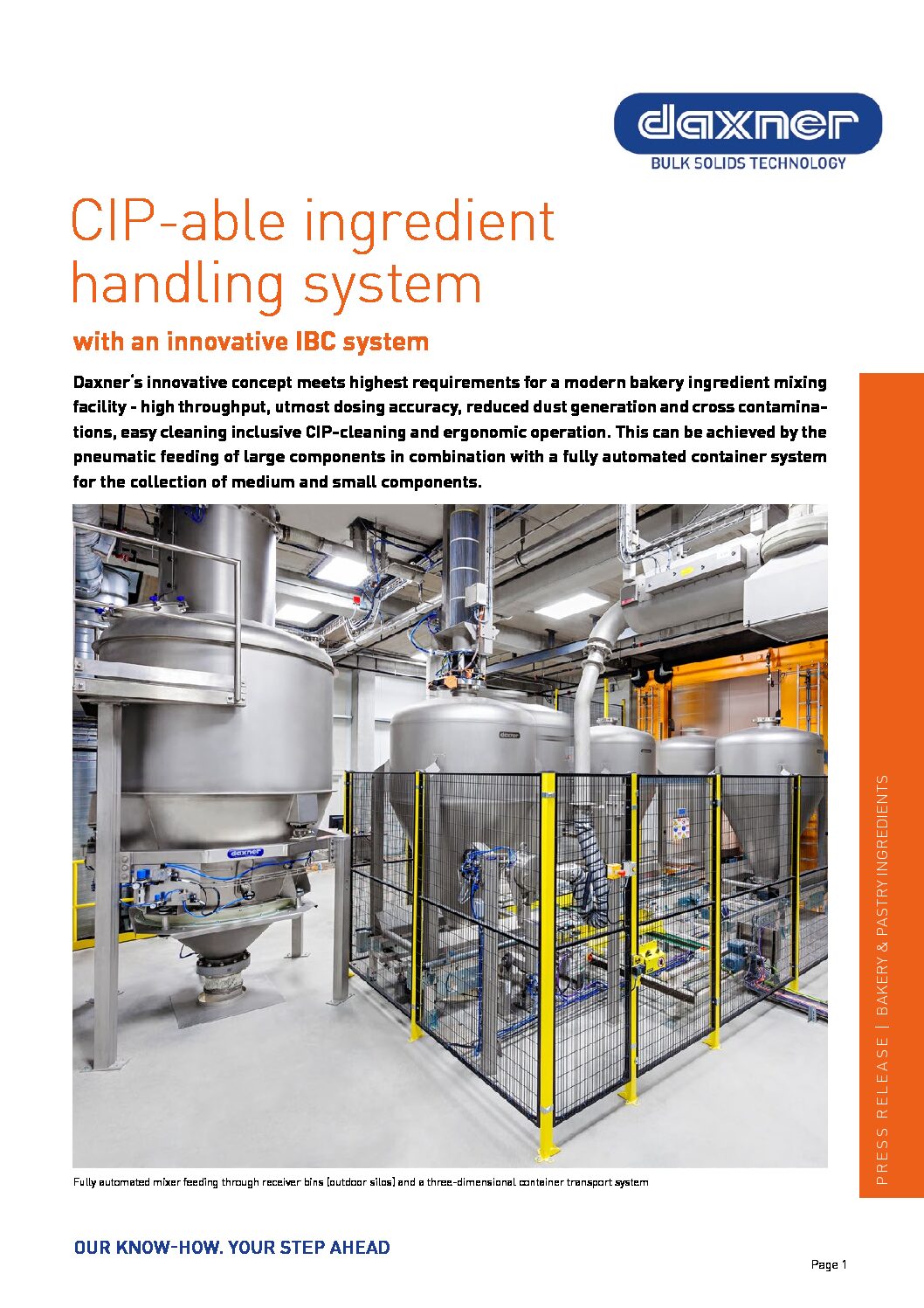

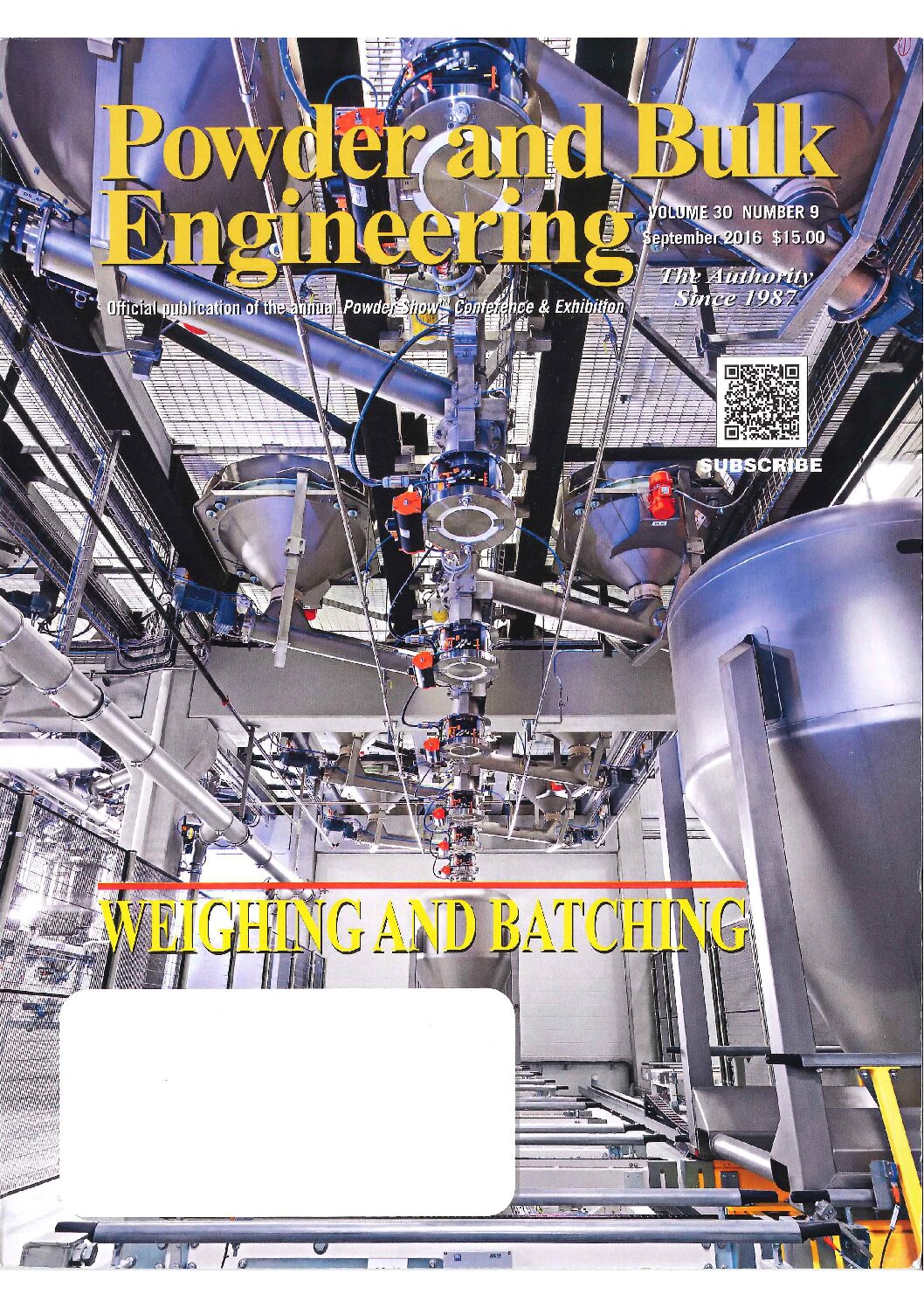

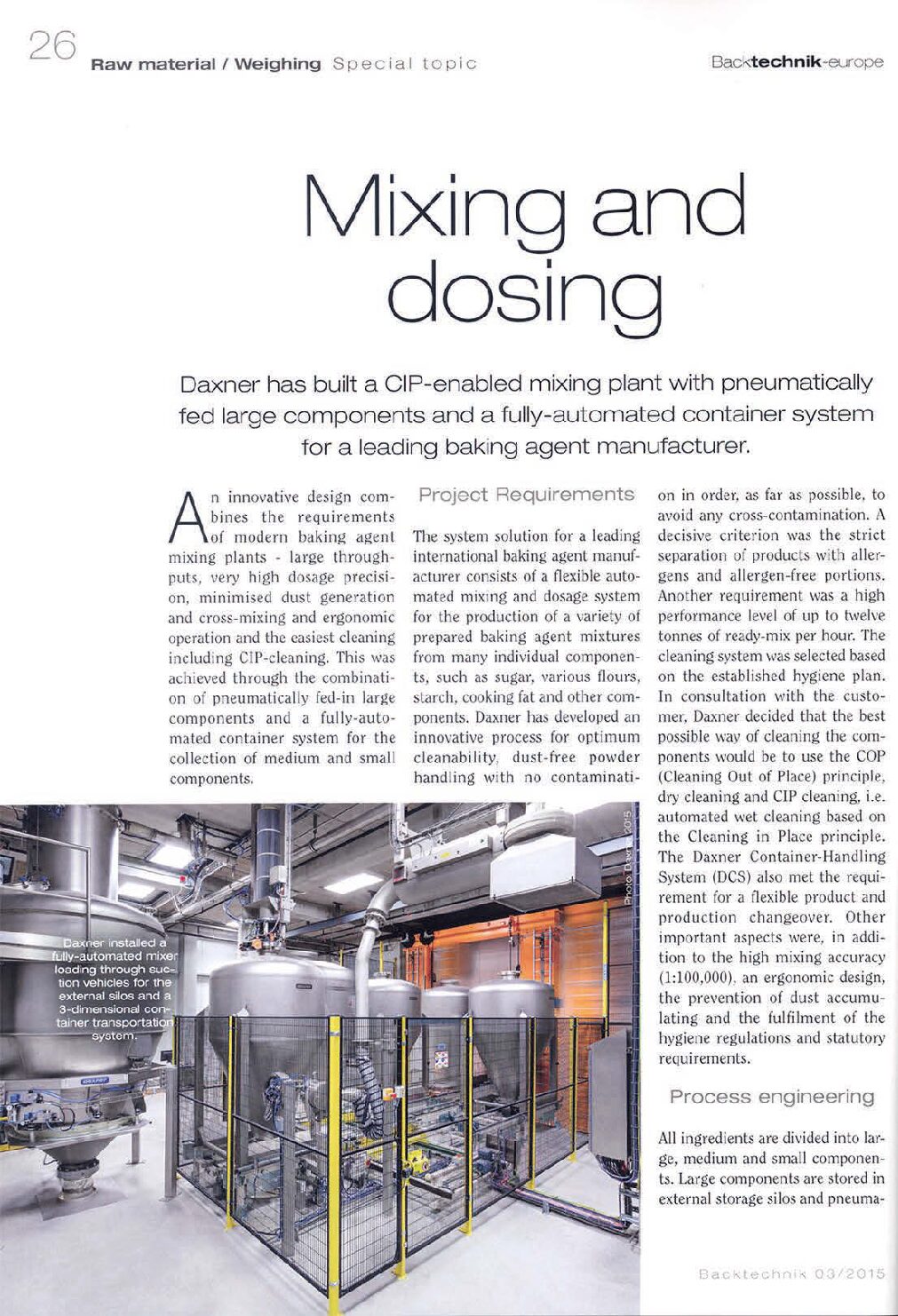

Daxner’s innovative concept meets highest requirements for a modern bakery ingredient mixing facility – high throughput, utmost dosing accuracy, reduced dust generation and cross contaminations, easy cleaning inclusive CIP-cleaning and ergonomic operation. This can be achieved by the pneumatic feeding of large components in combination with a fully automated container system for the collection of medium and small components.

Description

Daxner has designed a flexible, automated blending and dosing system for the production of various ready-made bakery ingredient mixes, which consist of a very large number of different ingredients, such as sugar, various flours, starches, cooking fat etc.

Daxner developed an innovative system with due regard to easy cleaning, dust-free powder handling and prevention of cross contaminations, in order to exclude reciprocal contaminations.

A decisive criterion is the strict separation of components, which contain allergens, from those products, that are allergen-free.

Project objectives:

- Design and delivery of a high performance mixing plant for the production of bakery ingredient mixes for bakery products (bread, cakes, cookies, confiture etc.) in compliance with state-of-the-art regulations. Prevention of cross contaminations, most notably of those handled ingredients which contain allergens.

- The following ingredients are handled without any contaminations and mixed homogenously:

Large components such as flour, crystal sugar, dextrose etc.

Medium components for example salt, sugar, starch etc.

Small components such as bread improvers, emulsifiers, spices etc. - High capacity up to 12 t/h ready-made mixes

- Maximum prevention of cross contaminations for all handled allergens, certified in accordance to BRC-regulations (=contamination free production below 10 ppm)

- Easy cleaning of the equipment in compliance with the regulations of COP (Cleaning out of place), dry-cleaning and CIP-cleaning, i.e. the automatic wet cleaning based on the principle Cleaning in Place. Depending on the hygienic concept, the best suitable cleaning system is selected.

- The Daxner Container-Handling System (DCS) allows a flexible product or production changeover.

- Highest mixing accuracy (1:100.000) for powder mixes inclusive the addition of block fat resp. liquid fat.

- Ergonomic design

- Prevention of dust generation

Process technology

All ingredients are divided in large, medium and small components. Large components are stored in outdoor silos and are pneumatically conveyed to the two mixing lines. Medium components are stored in daily silos which are fed by mobile intake stations with intregrated control screens.

The medium components are then dosed and weighed out of the daily silos into the below positioned container or IBC (Intermediate Bulk Container) by the means of a dosing screw conveyor with rough and fine dosing which is connected to the silo discharge device. A highly precise active and passive valve system enables the fully automated connection to the filling opening of the IBCs.

The mobile intake station VIB&PRESS (inclusive control screen and stirring device) fills the pre-commissioned small components directly into the IBC.

A three-dimensional container transport system, which consists of an automated storage and retrieval system with chain conveyors and a shuttle-system, conveys the IBCs fully automated to all collecting points (medium and small components), subsequently to the mixing line and finally to the discharge of the collected product batches. The IBCs are docked on and off at these stations. The mixing plant consists of a high precision vertical blender. The blending principle is based on a reverse flow which is generated by a rotating screw belt in the mixer. Block fat is dissolved in the mixer through cutting rotors. The geometry of the screw belt ensures that the product always runs through the cutting rotos.

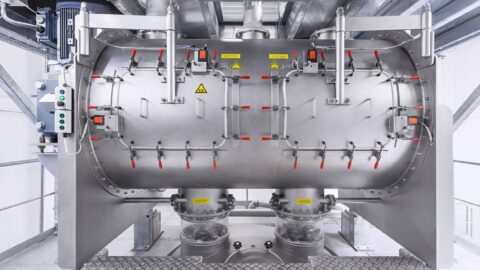

The design of the mixer is in compliance with the highest hygienic regulations – no edges and corners with utmost surface quality. The batch mixer discharges into the mixer receiver bin with an integrated stirring discharger, which simultaneously serves as a receiver bin for the high performance bag filling station. Both the IBC and the entire mixing line are equipped with a fully automated wet cleaning system (CIP), which covers the cleaning cycles, such as rinsing, washing, sterilizing, rinsing the product with clean water and a subsequent drying process.

Detailed technical solutions

a.) Container connection system with an active and passive valve system (CCS). This system meets highest hygienic requiremetns (pharmaceutical design) and consists of a stationary active valve und a mobile passive valve, which is mounted on the IBCs. Since simply the stationary active valve needs to be provided with electricity and pressurized air, the fully automated docking of the transport containers/IBCs can be achieved.

During the transport process the passive valves shut the in- and outlet of the IBC hermetically, whereupon the leakage of any transported product (allergene) can be completly prevented. While loading and discharging the IBC any dust leakage and therefore any cross contaminations can be prevented through the locking mechanism when docking onto the IBC. The complete assembly module of the active valve with the corresponding extraction mechanism enables a quick removal and transport of the complete IBC-connection module to the COP-Station.

b.) Automatic 3D-transport system; An automated storage and retrieval system for containers combined with a sophisticated shuttle-system conveys the IBCs in hygienic design fully automated to all collecting points of the components, subsequently to the mixing line discharge station.

c.) CIP-able mixing facility in hygienic design according to the regulations of EHEDG und HACCP. A completly rounded mixing chamber, no horizontal surfaces and an optimized mixing technology ensure the highest level of hygiene and easy cleaning. Additional, strategically positioned spray heads and spray nozzles enable a completely automated wet cleaning and a subsequent drying of both mixer and the equally designed mixer receiver bin inclusive connection piping.

d.) Fully automated CIP wet- und dry cleaning stations for IBCs.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.