This plant solution for one of the most modern spice blend producers in Europe covers the whole production process: Ranging from raw material retrieval, its filling, weighing and blending to the bagging of the finished spice blends. The complete system design meets highest requirements in terms of quality, efficiency and flexibility.

Description

Intelligent IBC handling system

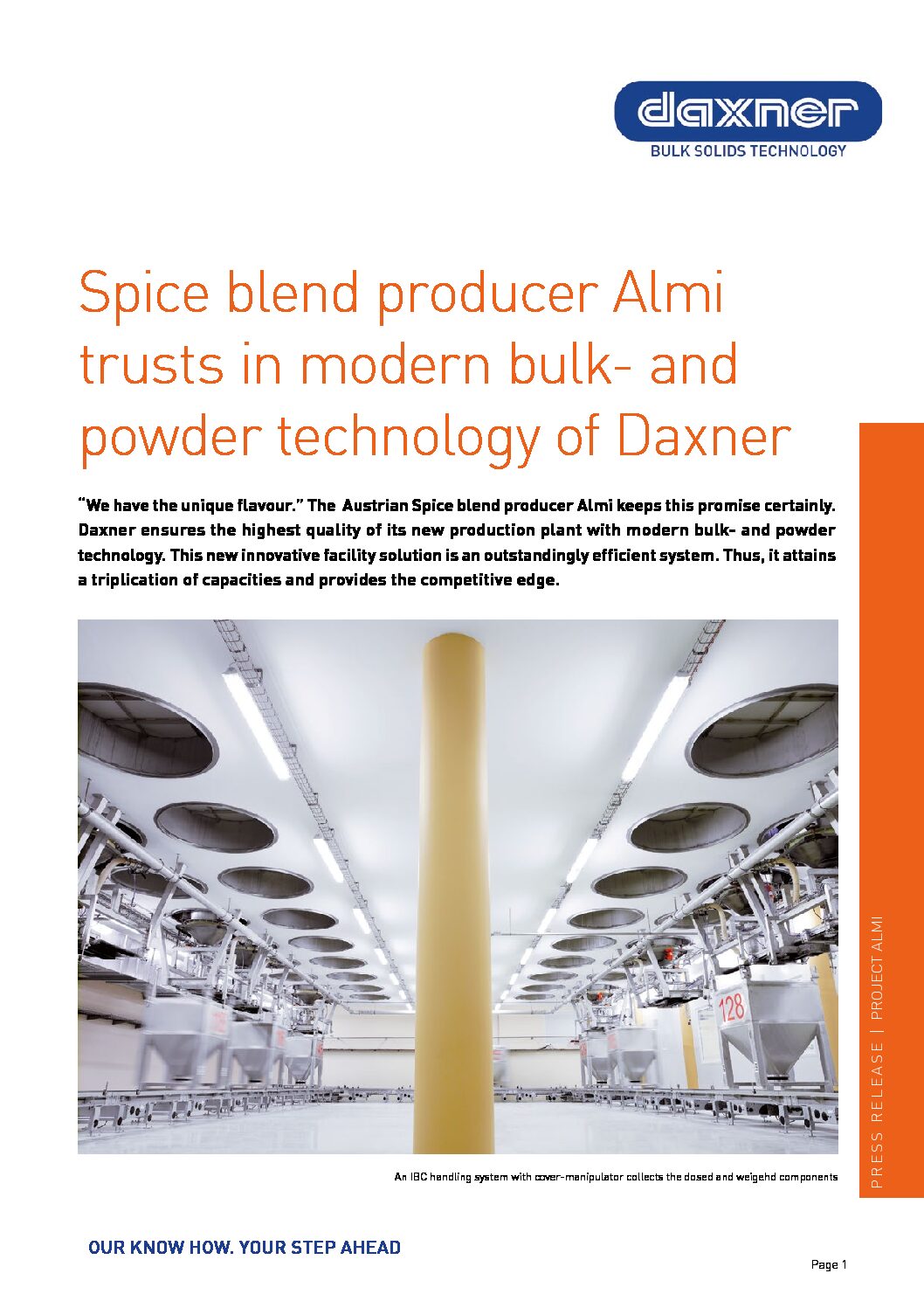

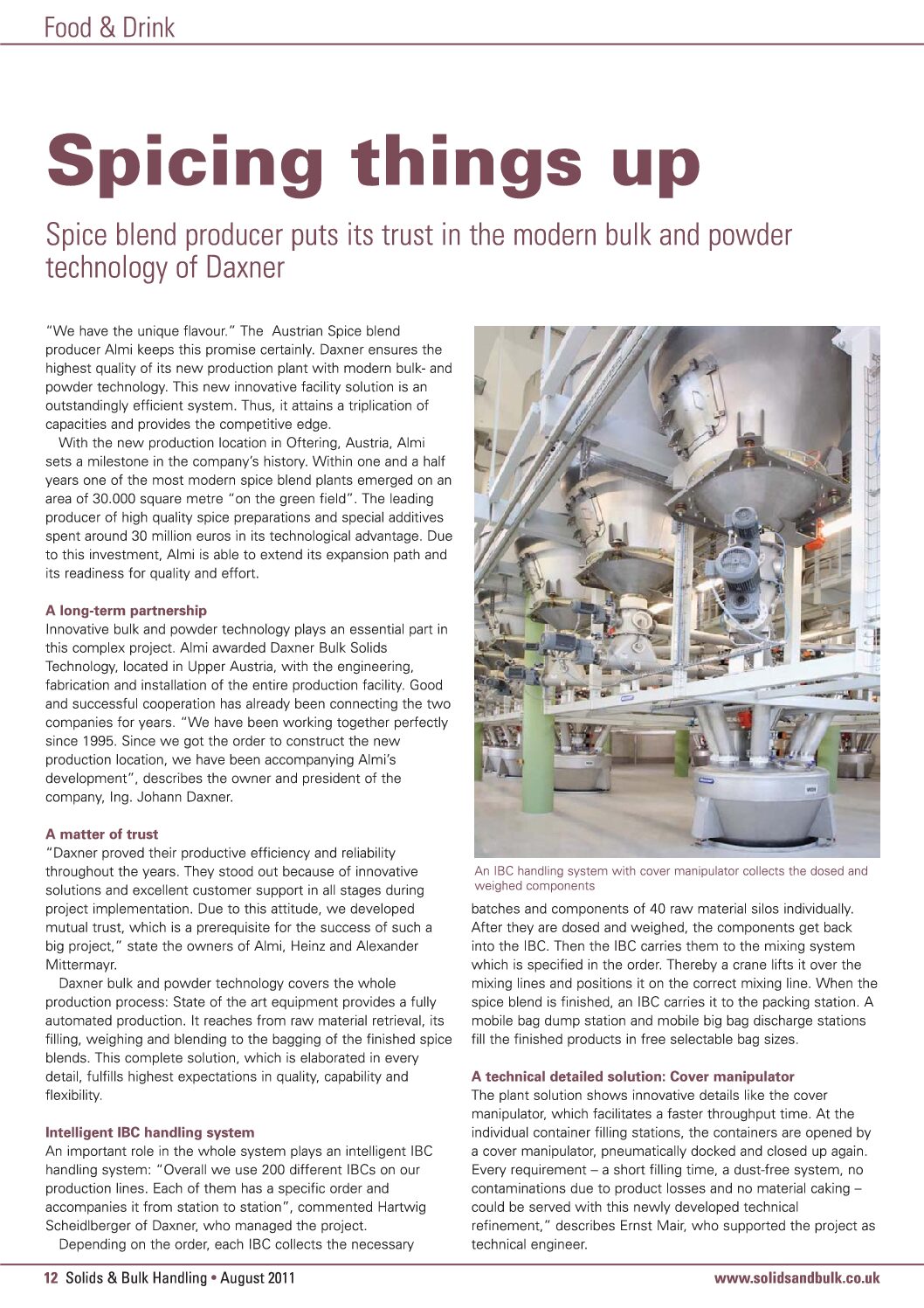

An important role in the whole system plays the intelligent IBC handling system DCS (Daxner Container Sytems): Overall there are 200 different IBCs on the production lines. Each of them has a specific order and accompanies it from station to station. Depending on the order, each IBC collects the necessary batches and components of 40 raw material silos individually. After they are dosed and weighed, the components get back into the IBC. Then the IBC carries them to the mixing system which is specified in the order.

Thereby a crane lifts the IBC over the mixing lines and positions it on the correct mixing line, then the IBC is docked and discharged without any residues by a container discharge system. According to the size of the batches and recipes the mixing lines distinguish themselves in terms of the blender size and the implemented mixing system, in order to ensure utmost mixing accuracy, mixing capacity and gentle product handling. When the spice blend is finished, an IBC carries it to the packing station. A mobile bag dump station and mobile big bag discharge stations fill the finished products in free selectable bag sizes.

A technical detailed solution: Covermanipulator

The plant solution shows innovative details like the cover manipulator, which facilitates a faster throughput time. At the individual container filling stations, the containers are opened by a cover manipulator, pneumatically docked and closed up again. Every requirement – a short filling time, a dust-free system, no contaminations due to product losses and no material caking – could be served with this newly developed technical refinement.

Multiplicated dosing power

The system reaches a maximum dosing capacity together with a very high dosing accuracy through a separate, fully automated dosing system for small and medium components. These criteria – high accuracy and large throughput – are met by the means of separate screw conveyors for small and medium components – both equipped with with rough and fine dosing, and separate weighing bins which are directly positioned above the screw conveyors.

The flexibility of the container system DCS considerably contributes to the performance: An IBC at 1.000 kg each with a finished dosed batch can be provided every five minutes. That meets an hour capacity of twelve tons.

Highest possible flexibility

The new production system also demonstrates best practice when it comes to flexibility. It may produce and deliver customer oriented orders very rapidly. The production also allows to adopt to composition changes or additional orders in a few hours.

Process control system

A controls system which is included into the ERP-system, covers all production processes. Because of its comfortable handling, it allows complete retraceability and parallel order processing. In addition to the coordination of the whole IBC handling system, the controls system allows a takeover of manual dosed small and middle components without problems. These components are previously filled into Big bags or trays and placed on pallets for ready, time-independent further processing. According to the batch they are marked and adminstrated in the ERP system.

A new benchmark of quality

The IBC handling system allows an absolutely contamination free production in connection with best economic efficiency. This is especially important due to the amount of differing customer-oriented recipes and orders. In the case of a fix mounted bin, it would have to be cleaned every single time. But with this chosen solution, the plant is working without interruptions, because of the big number of IBCs. Thus, the capacity factor is much higher. In addition, anti-allergenic production is possible and the mixing process takes place with highest accuracy and inclusion of aroma- and extract additions in the micro-range.

Best quality for sure

In order to ensure the high quality of products, the whole production process includes control mechanisms. Daxner’s new developed VIB & PRESS control facility is able to carry out product intake and gentle screening of difficult products, which tend to form lumps. Magnet- and metal detectors ensure security, too. In general, the plant complies with highest standards which are required for the foods industry, such as ISO-9000, HAACP and IFS.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.