Functional description and benefits

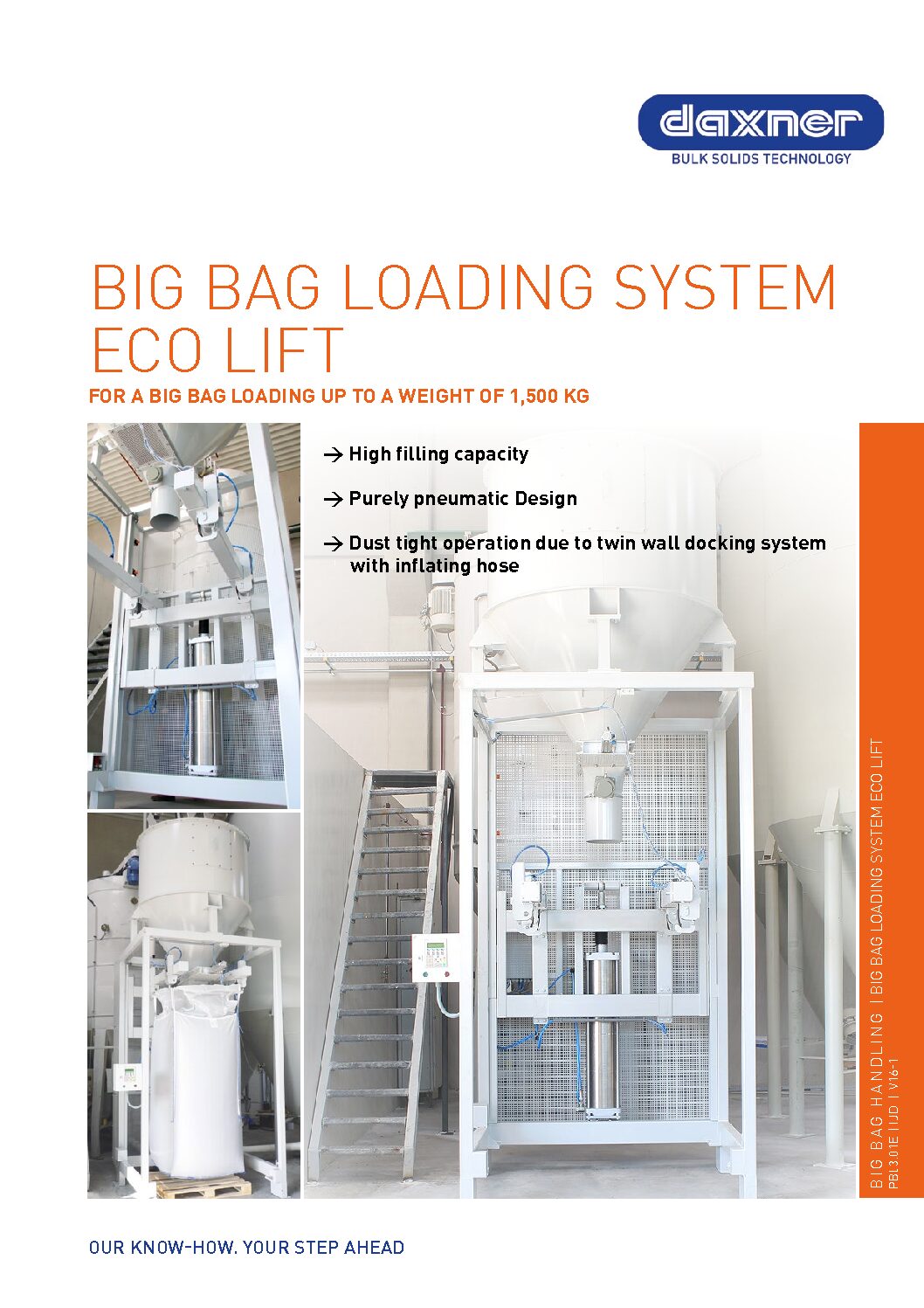

The ECO lift is designed for loading Big bags weighing up to 1,500kg. It can be adapted to various Big bag heights. The weighing electronics are easily calibrateable.

According to the product characteristics, the material is filled into Big bags by a dosing screw conveyor, metering-band or vibratory feeder.

The lifting and lowering of the loading spout and the loop release mechanism are implemented pneumatically.

Particular emphasis was placed on user-friendly operation, including an ergonomic design with a comfortable working height when hanging and fixing the Big bags into place. The Big bag is then lifted into its loading position to start the process. For a better and more stable material distribution, the pre-defined “compacting function” can be activated during loading.

When loading is finished, the Big bag is placed on the roller tracks and optionally transported out by powered rollers. The pallet dispenser discharges empty pallets automatically.

The unit operates dust free by using a twin wall loading spout design and an airtight inflation hose bag interface.

A twin wall connection socket is connected to the aspiration system. The bag loading station can also be adapted for the loading of containers – without changing the system setup!

Easy controller configuration and a clear user interface ensure the simple handling of the device. Optionally, a touch screen with process visualization can be added to the system.

Advantages

High filling capacity

High weighing accuracy

Dust tight operation due to twin wall docking system with inflating hose

Variable Big bag sizes

Calibrateable weighing controller

Easy to operate for one person

Maximized operator safety

Automatic loop release

Material compacting function for efficient filling

Optional roller tracks for automatic bag transport

Hygienic Design

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.