Functional description and benefits

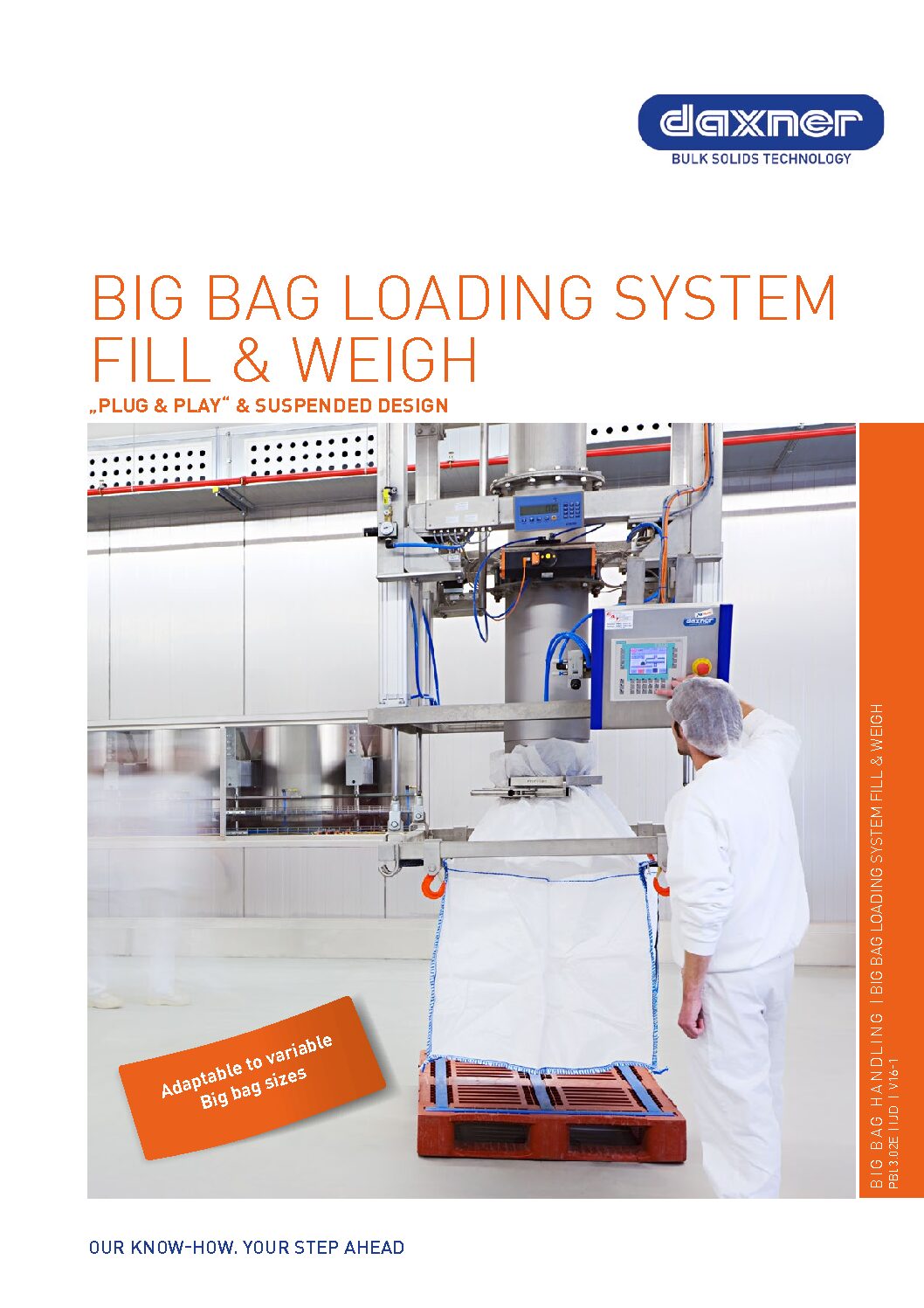

The FILL & WEIGH is a Big bag loading station with a pallet-scale, pneumatic lift, weighing terminal, and a readily wired “plug & play” design.

The operator places the bag loops into the loop holders, slides the bag socket over the loading spout and tightens the bag torque clamp

The operator simply selects the desired filling & dosing program on the controller and starts loading. After the Big bag loading is finished, it is placed on the pallet and the loops are taken off easily. The U-shaped pallet scale allows easy removal of the loaded Big bag by a forklift truck or trolley.

Advantages

Adaptable to variable Big bag sizes

User friendly, ergonomic design

Material compacting function for efficient filling

Maintenance-free, water proof pallet-scale

Calibrateable, easy-to-use weighing controller

Minimized dust leakage due to twin wall connection socket

U-shaped pallet-scale for the operation with a fork lift

TCP/IP interface for ERP systems

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.