Functional description and benefits

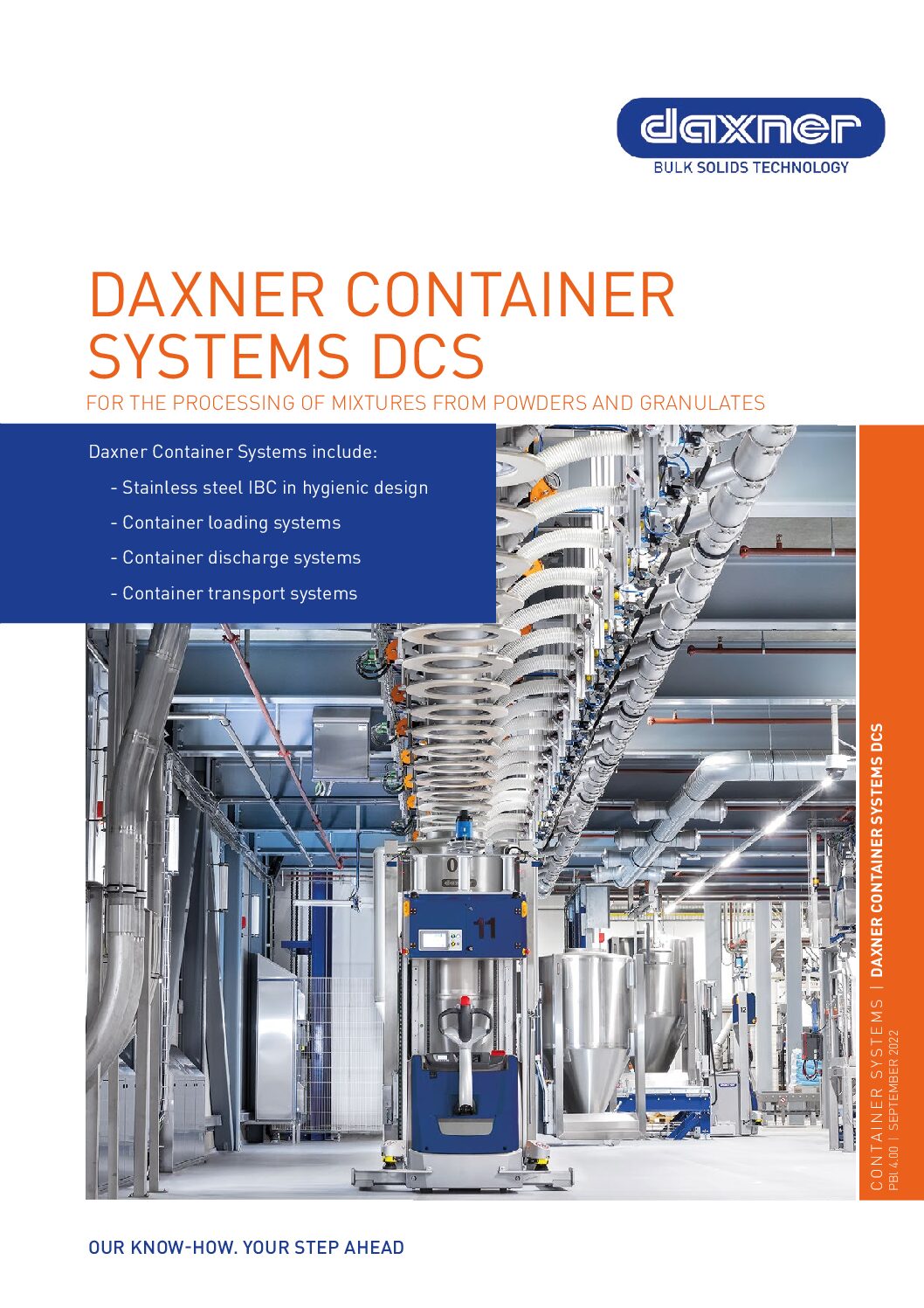

Container systems for the handling of bulk solids using containers (IBC’s): The IBC transport within the system can be implemented according to specific requirements by forklift, powered roller-tracks, automated guided vehicle or stacker cranes.

Container systems include the following processes:

- Storage – dosing of raw materials (small components)

- Filling – weighing of raw materials into batch containers

- Mixing/blending inside the container (gravity blender, container blender)

- Loading and intermediate storage of predetermined batches in containers

- Container discharge into packaging machines

Advantages

Maximum flexibility

Elimination of cross-contamination

Customized solutions

Automatic, exact dosing of small batches down to grams

Controls with visualization, protocols, and complete traceability of batches

Residue free container discharge

Easy cleaning of containers

Optional Easy Clean discharge and dosing equipment (dosing screw conveyors etc.)

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.