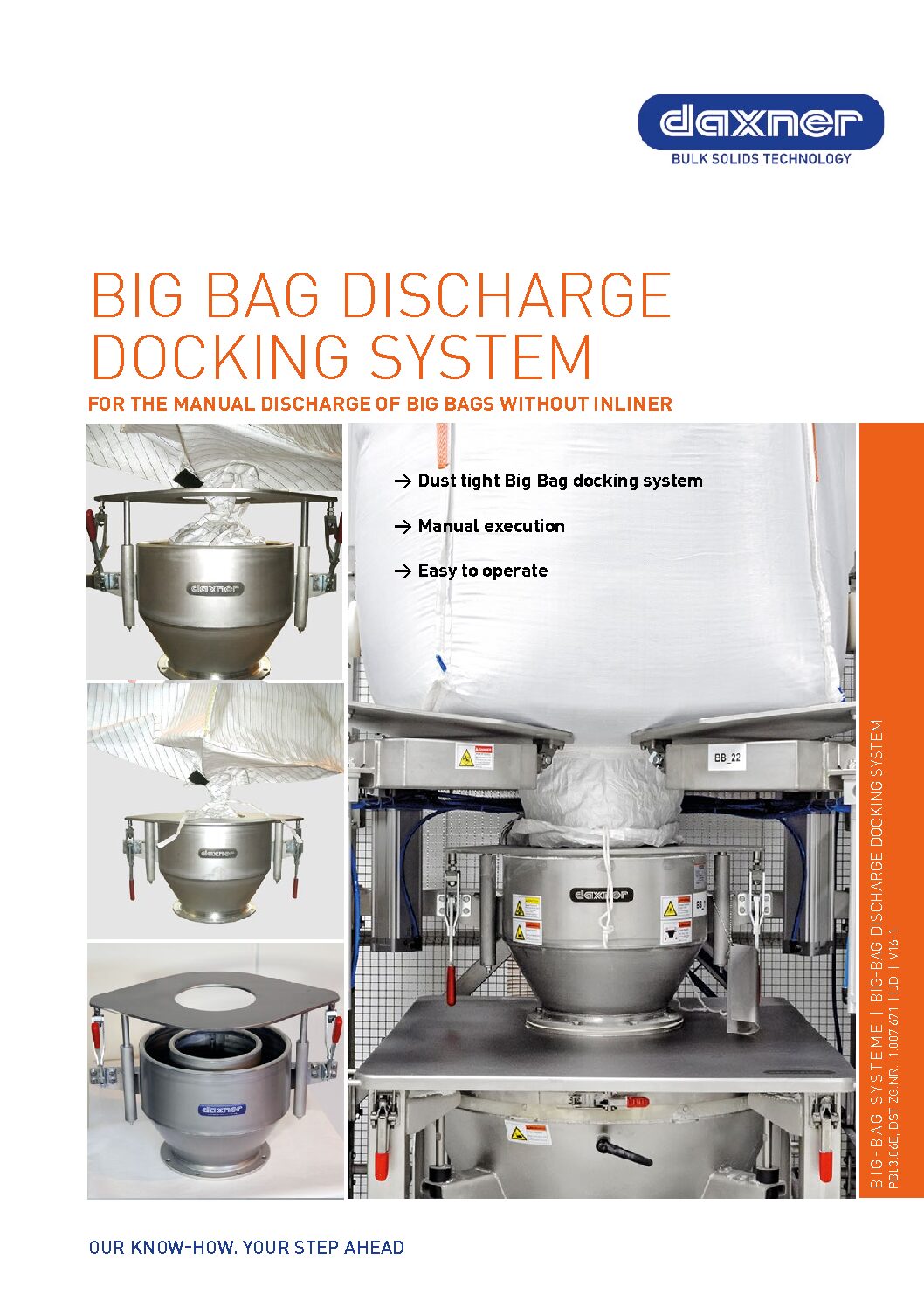

Daxner’s dust-tight Big bag docking system is designed for the manual discharge of Big bags without an inliner. The operator slides the loops over the loop holders. Now the bag can be lifted up by the electric hoist and positioned along the hoist-track. Once the bag is positioned just above the docking system, the Big-bag out-feed hose is slipped over the inner connection socket. Now the discharge can be started.

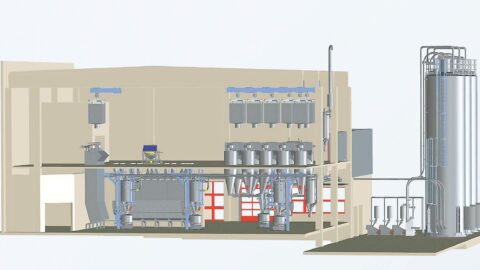

Both, a special sealing and dust collection for the space between the inner and outer connection socket, prevent dust generation. Optional discharge aids for products with poor flow characteristics are bag massagers or vibro-discharge cones. Big bag dosing stations are implemented for the automatic dosing of components. Big bags are positioned on the docking station with the help of a hoist. The manually or pneumatically activated docking mechanism provides a safe and dust-free Big bag discharge.

Advantages

Dust tight operation due to twin walled docking system for dust control

Easy to operate for one person

Reliable discharge

Robust construction

Maximized operator safety

Optional massager- or vibro-discharge aids

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.