Functional description and benefits

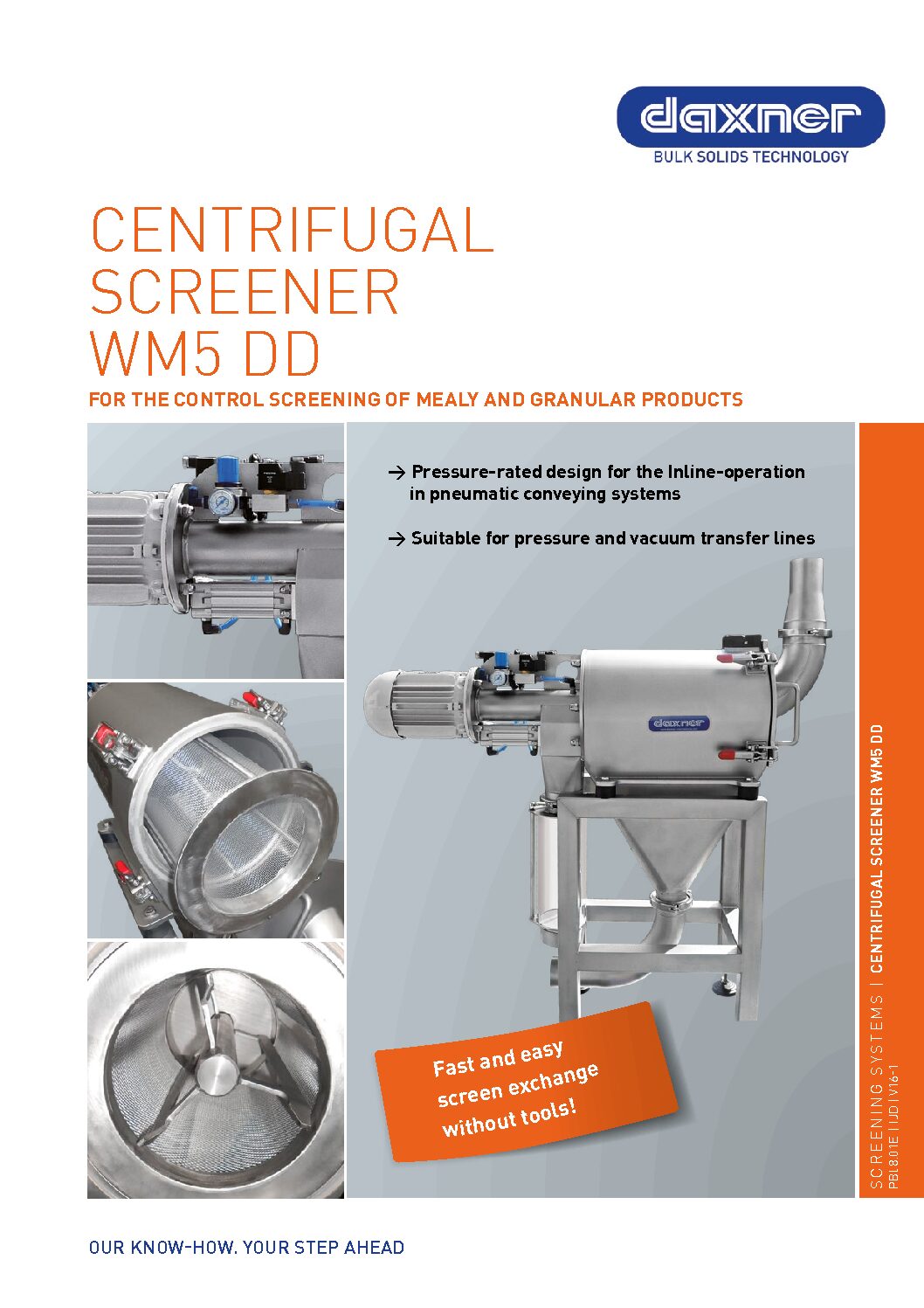

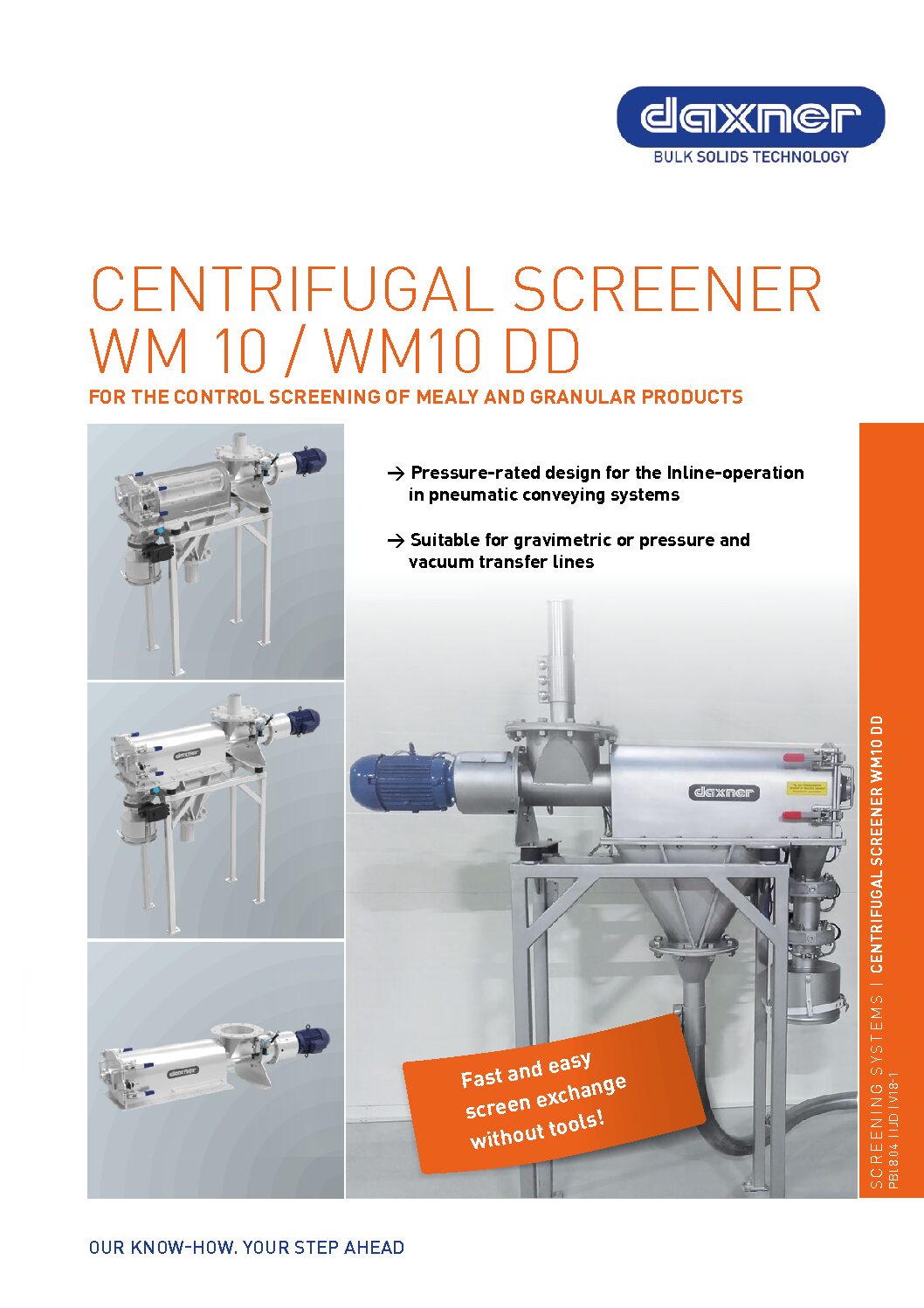

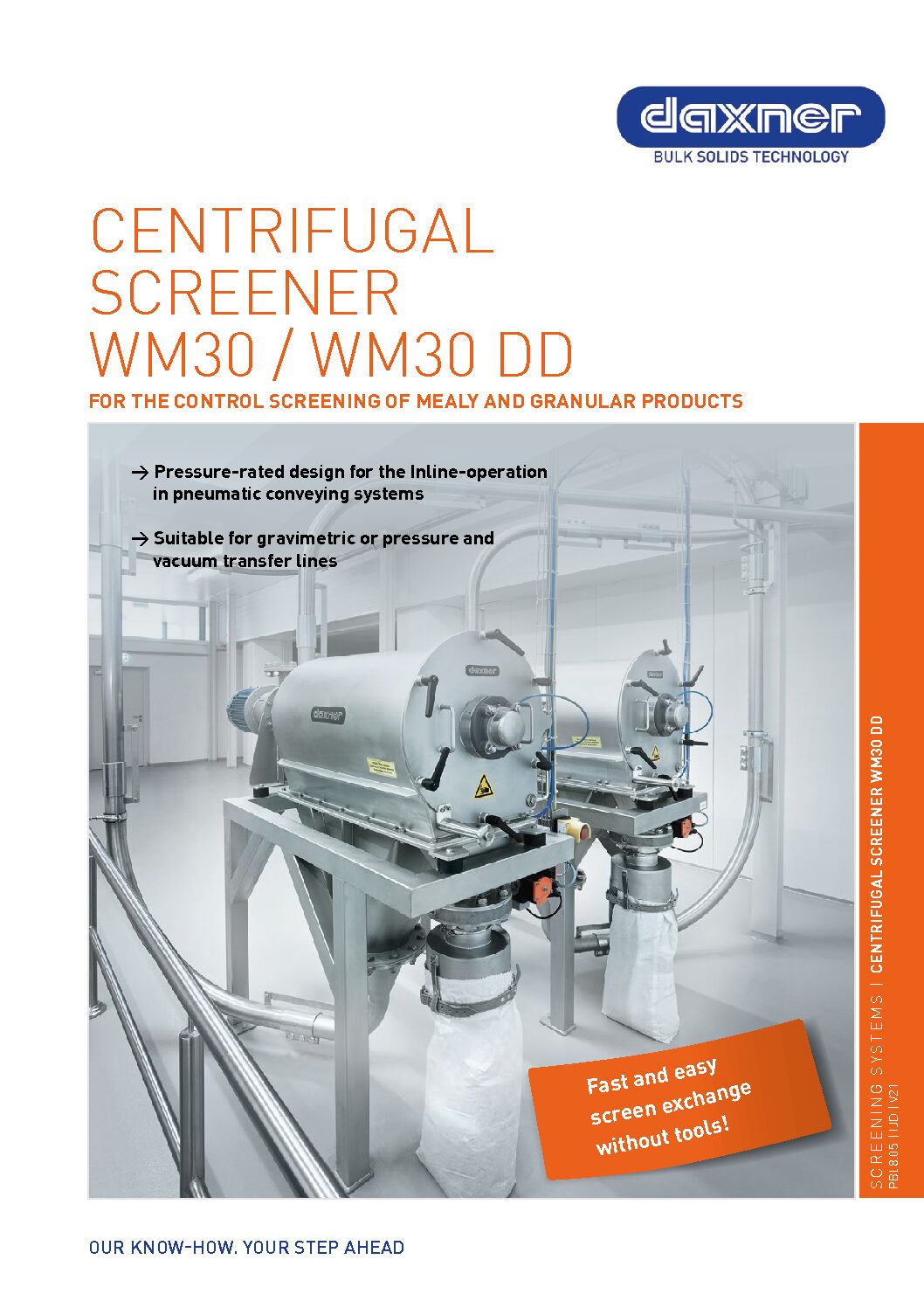

Centrifugal screeners are used for the efficient control screening, fractioning and de-agglomeration of powders and granulates.

The rotating screw generates centrifugal force, which presses the material onto a stationary screen. Particles smaller than the screen mesh width pass through the screen, whereas particle larger than the mesh width travel along the screen and are deposited at the oversize outlet.

This device enables easy and fast cleaning, it can be dissambled without the use of any tools.

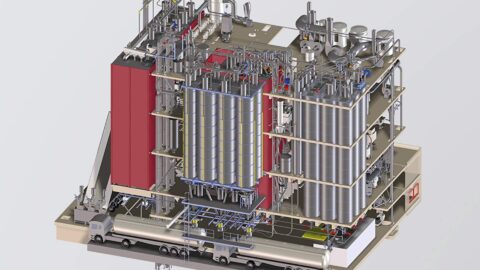

According to the specific product characteristics, the centrifugal screener comes in different sizes and with various design features.

Optionally the screeners are available with a dosing screw at the intake and a built-in magnet separator with nylon or metal screens.

Designed for either gravimetric operations or pneumatic systems.

Advantages

Efficient, economic screening

Fast & easy screen change without tools

Easily integrated into existing processing systems

Large throughput performance

Hygienic Design

Optional dust explosion rated design (ATEX)

Robust design

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.