Functional principle and benefits

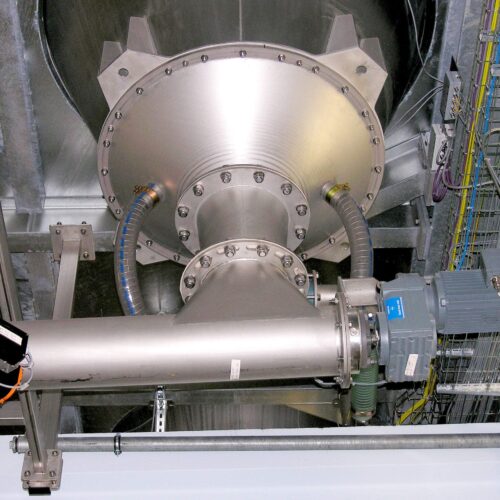

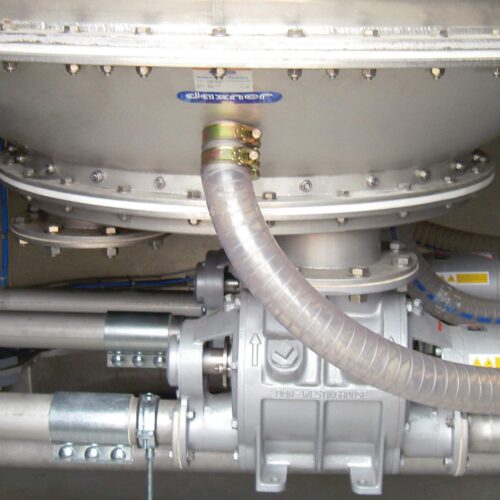

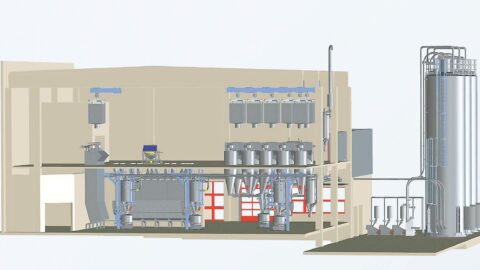

The fluidizing bin discharger is used for the discharge of powders with poor flow characteristics out of silos/bins, which can be fluidized by the introduction of air.

A jacketed housing provides aeration along the activator wall which causes the material to behave fluid-like and hence flow out smoothly and evenly.

A typical application example is the discharge of flour.

Advantages

No mechanical moving parts

Self cleaning design

Low energy consumption

Minimal, inexpensive maintenance

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.