Functional principle and benefits

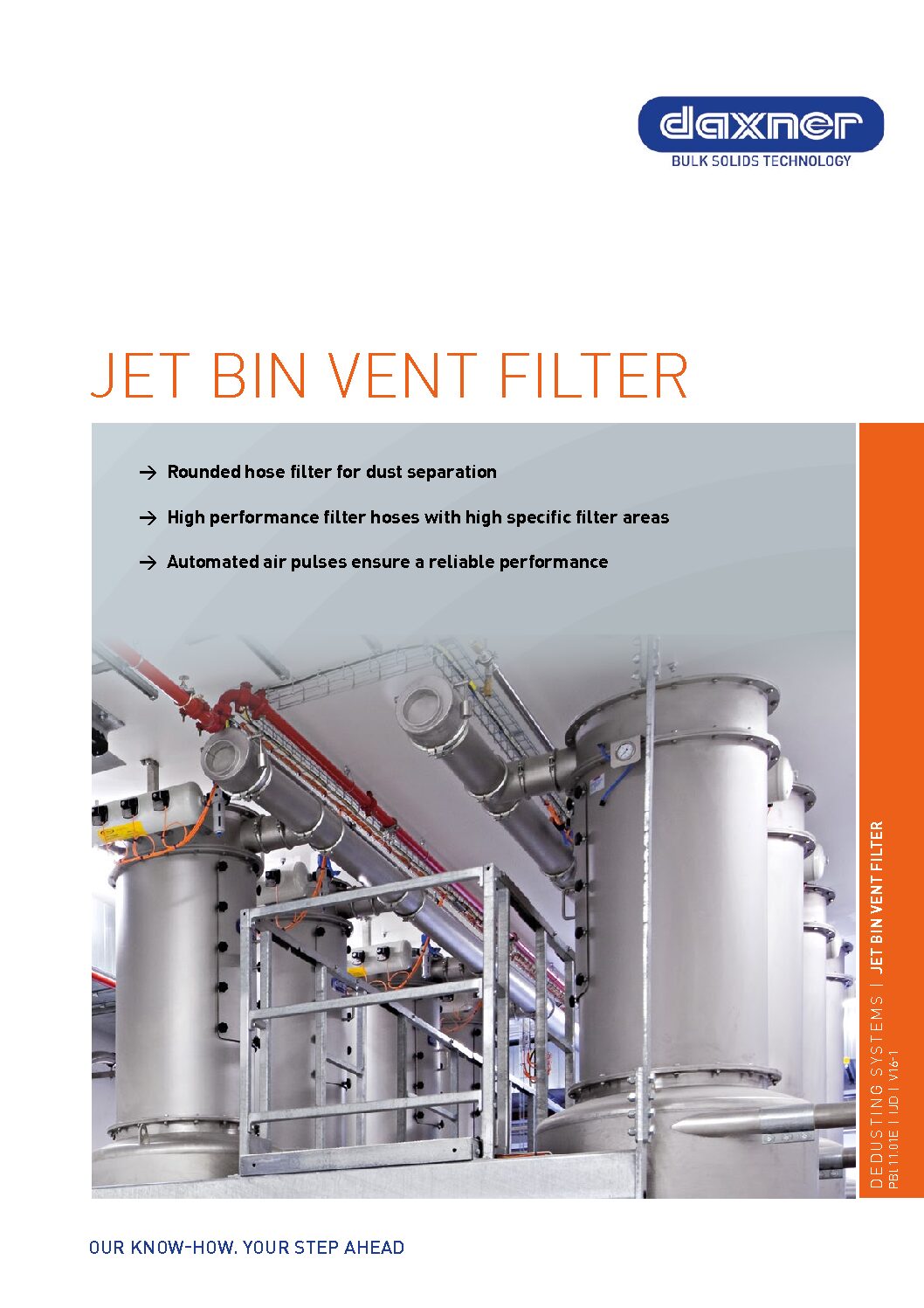

Jet Filters are used for dust control in silos and bins. The separation of the material/air mixture into clean air and dust happens in the silo hoses (or cartridges).

The Daxner Jet Filter provides a fully automated and maintenance-free operation. Nozzles pressurize the filter hoses with pulses of air which clean them from the remaining dust. This requires oil-free, pressurized dry air with 6 – 8 bars. The controls system activates the nozzles in a periodical sequence.

Quick action clamps assure an easy disassembly for cleaning and inspection. The easy hose exchange system allows the exchange of the complete set of filter hoses within seconds by simply opening the door and lifting them out.

This system allows a quick filter exchange between different products e. g. colors and allergens.

The pressurized air is directed into the filter hose via a direct injection and venturi. The volume and pressure of air cleans the filter hoses from the inside leaving the external surface.

Advantages

High performance filter hoses with a large load capacity

Automated air pulses ensure a reliable performance

Round filter housing

Clean air quality is exhausted

Only requires small amounts of pressurized air for effective hose cleansing

Easy bag exchange at the clean air side on the filter top

Optimal sliding-hose exchange system for easy cleaning

Tool-free dismantling of the filter

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information