Functional description and benefits

Loss-in-weight feeders are implemented for the continuous dosing of floury and granular materials. The dosing capacity reaches from 20 up to 200 l/h.

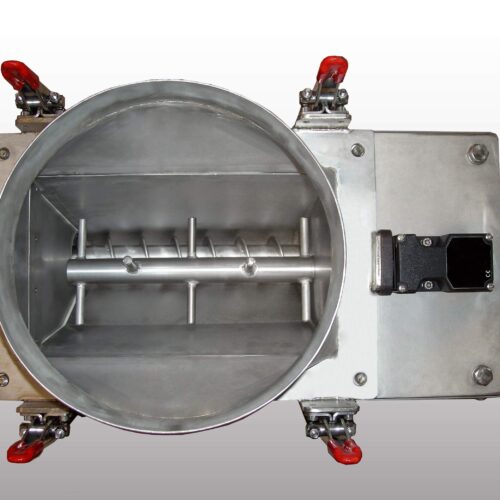

Material is loaded into the inlet hopper. Paddles provide a continuous discharge into the dosing screw conveyor. A variable frequency drive regulates the speed of this high precision dosing screw. Afterflow is prevented by a flow stop flap at the discharge end.

The easy cleaning, retractable design allows for a fast cleaning of the entire device without the use of tools.

Advantages

Continuous, safe material dosing

Fast & easy cleaning by retractable design of the face plate

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.