Functional principle and benefits

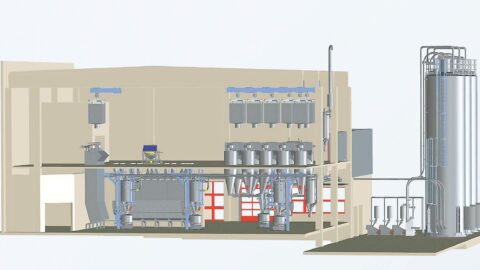

Daxner’s outdoor silos provide the basis for high-end product quality. Our custom designed silo solutions which are tailored to the specific product characteristics, enable an excellent product flow and smooth production processes. In due consideration of the available space we take care that the maximum of storage capacity is achieved.

Since we are not bound to fixed silo diameters, we can choose between a multitude of solutions within a given set of (space-) constraints. At the same time, this gives us the possibility to optimize interfaces of connection systems and devices as well. Daxner delivers a complete turnkey system including filling, discharge and conveying equipment, as well as the complete controls system.

Typical discharge systems include vibro bin dischargers for sugar discharge, fluidization discharge cones for flour discharge etc.

A bunker jet filter, typically equipped with filter hoses, or cartridges cleaned off by an air purges are responsible for dust control.

Advantages

Custom designed silo solutions

Complete turnkey design including dust collection, discharge, conveying, dosing, controls system; engineering, fabrication and installation

Support styles include: long & short skirt, load cells, structural supports etc.

Available in aluminium, stainless steel and coated carbon steel

Excellent product flow through a very smooth surface finish

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.