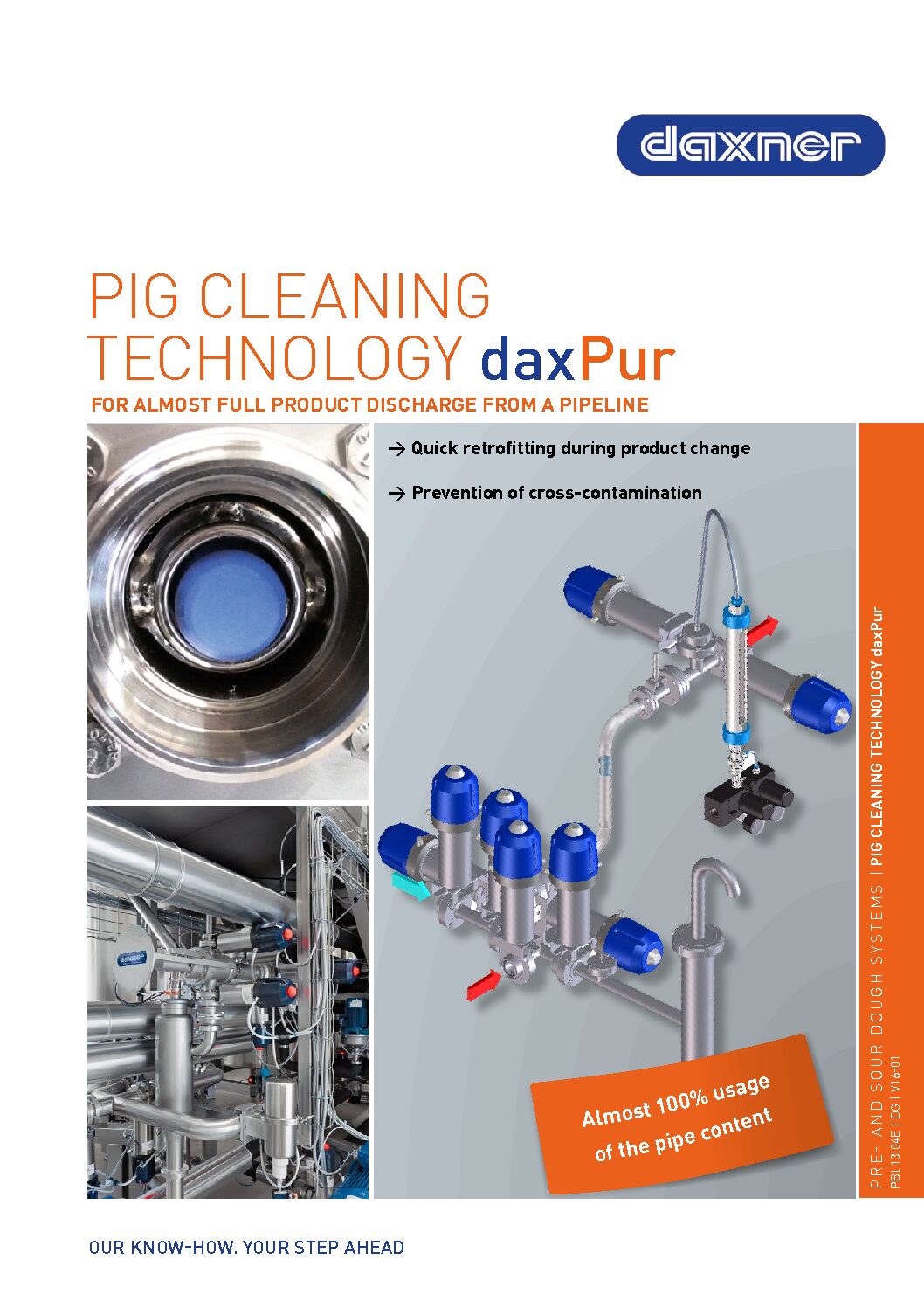

Functional description and benefits

Pipeline “pig” cleaning technology daxPur will be used mainly for product release (almost 100% use of product possible) or for a clear separation of sequenced product batches in pipelines. On the other hand, pig cleaning technology daxPur will be also used for cleaning of the pipeline (CIP-cleaning possible) after product flow. The operation-process normally should not be interrupted.

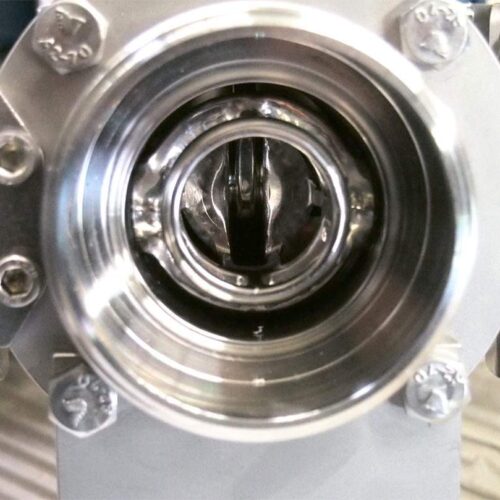

The pig completely fills the line cross-section and moves either with the product flow through the pipeline or is pressed through it via extra used pressure (created with water or compressed air).

For using the pig cleaning technology not only pigs, also charging and extraction stations are required. The pig will be inserted at the charging station and applied with pressure. Having cleaned the relevant section, the pig can be ejected at a special extraction station. The relevant pigable valves are able to open the cross-section completely, like e.g. ball valves and shut-off valves.

Field of application of the pipeline “pig” cleaning technology daxPur:

- Pre-dough / sponge

- Sour dough

- Liquid yeast

- Oil, fats

- Confectionery, cream fillings, chocolate

- Beverage industry, syrup

- Food industry (e.g. ketchup, sauces), meat industry

- Raw materials, e.g. concentrates

- Paper industry

- Color industry

- Liquid binding agent, starch glue

Advantages

Enables the full product discharge from a pipeline

Minimizes downtime between product changeover

Prevention of cross-contaminations, no mixed phases

Mechanical pre-cleaning of the pipeline

90% saving on rinsing water due to low pollution load

Lower burden on waste water treatment plants / sewage management

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.