Functional description and benefits

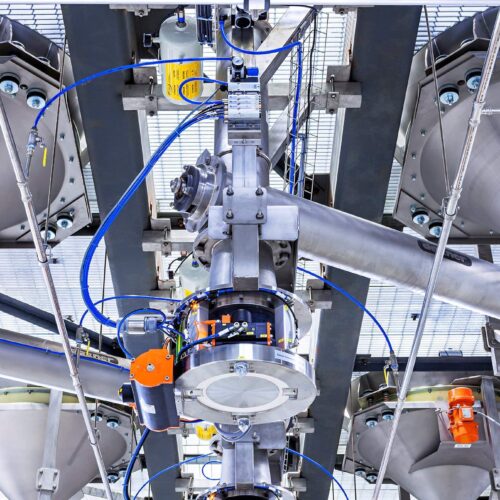

The material is fed into the product inlet and is then gently conveyed through the screw conveyor by the helix blades. The throughput is determined by the rotational speed and can be controlled with a variable frequency drive.

By carefully selecting the correct design parameters, one can convey almost any dry material with a tubular screw conveyor. Various design implementations yield optimized solutions for various customer requirements. Examples are easy clean features, air purge fittings for meeting highest hygienic standards, and using the right material and surface finish for the corresponding application at hand.

Optional design for fast disassembly without the use of tools for quick cleaning and inspection.

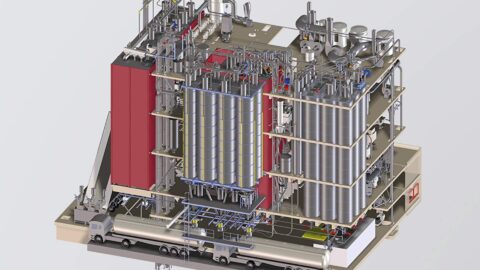

Dosing screw conveyors are used for dosing the exact component quantity into a container or scale. Different speeds for coarse and fine materials combine a high throughput volume and exact dosing.

A great bandwidth of sizes and design features provide the suitable solution for specific customer requirements in the foods-, chemical-, animal feed- and plastics industries.

Advantages

Flexibility – wide range of sizes & design features

Customized solutions

Exact design to minimize material residue

Optional fast disassembly features allow for quick cleaning and inspection without the use of tools

Hygienic Design

Optional dust explosion rated design (ATEX)

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.