The company is one of the most important European manufacturers of mineral and active ingredients for nearly all types of animals. A multitude of different small components give rise to special, highly effective feeds. This requires absolute precision in their dosing and weighing, because even the smallest deviation can significantly affect their quality. The accuracy of the automatic dosing and weighing system developed by Daxner is 10 grams per component.

Description

No conflict between precision and productivity

The system succeeds in balancing precision and productivity. Not only the dosing and weighing accuracy, but also the dosing capacity is right: up to 12 batches per hour can be handled, which is a significant increase in comparison to its original capacity.

Optimizing production

The advantages are obvious: In this case, technology not only provides higher efficiency and precision, but also an optimization of the whole production area. Spatial constraints are finally eliminated. Because dosing was positioned on the ground floor, and weighing in the basement, the long-needed additional space was obtained for the mixing area.

Residue-free handling of difficult materials

Despite the individual production steps being set up on different levels, the production process works completely trouble-free: A pneumatic dense phase conveyor transports the dosed and weighed components from the basement to the mixing process on the fourth floor. Defying the laws of gravity, they arrive completely free of residue and contamination, and meet the strict hygienic requirements to 100 percent.

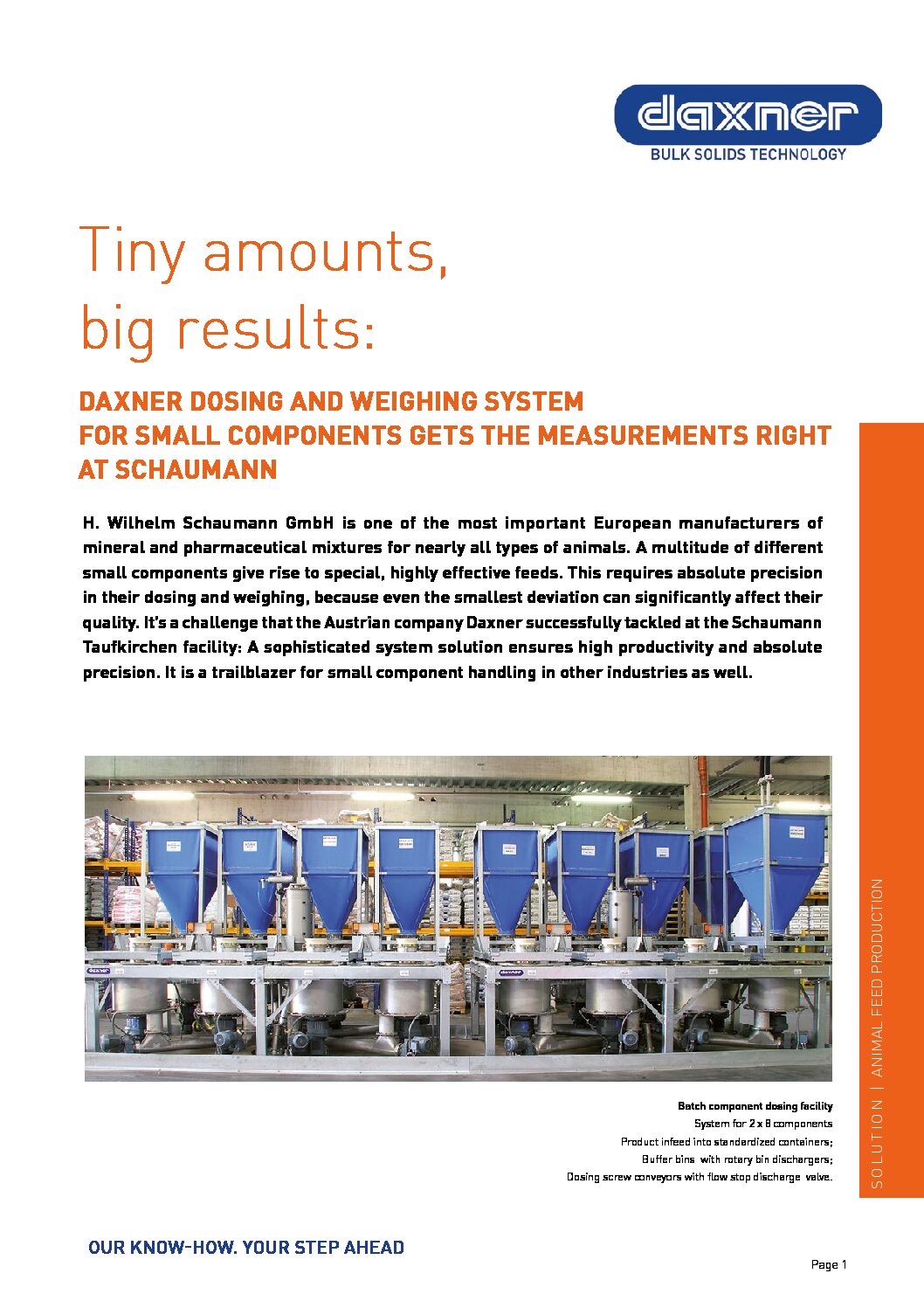

Combined intake stations

The company stores the small components necessary for the mineral mixtures — trace elements and vitamins — on the ground floor. Two combined intake stations equipped with a control screen, fill the ingredients out of Big bags or bags into the containers. An inflatable hose docking system and a powerful aspiration system with a radial fan and jet filter allow a dust-free filling.

Container dosing system

The containers are a central element in the small components handling. They are designed as a stable steel frame with flexible, clamped containers including a filling lid and discharge flap. After they are filled, they are guided to the dosing system, which consists of two dosing stations, each with eight container locations. Forklifts use docking collars to set the containers onto vibrating frames. The vibration ensures a residue-free discharge into intermediate bulk containers. Rotary bin dischargers uniformly feed the dosing screw conveyors. Exact production, speed control and the flow-stop sealing cap ensure precise dosing.

Flexible scale

Then weighing takes place in a flexible scale. It is designed as a container scale with flexible rubber inliners. Together with pneumatically actuated massagers they guarantee residue-free discharge even of powders with poor flow characteristics. To ensure strict hygienic requirements, it can be moved out on tracks for easy cleaning. Another plus: High weighing accuracy of 10 grams (weighing ranges up to 50 kg), allowing individual components of 1 kg to be weighed to 1% accuracy.

Pneumatic dense phase conveyor

Consequently the flexible scale discharges the weighed components directly into the below positioned pneumatic dense phase conveyor. This moves the bulk material from the basement to the receiver bin on the fourth floor. Despite the complex and long distance, even sticky material or products with poor flow characteristics can be gently transported with absolutely no residue. The conveying line ranges over a 30 m horizontal and 30 m vertical distance, in which a total of six 90-degree pipe bends are installed. These are designed as flexible hose bends for highly adhesive products. The receiver bin, which is antecedent to the mixing process, is designed as a scale, in order to ensure 100 percent residue-free conveying and discharge by using a gravimetric controls. The material is then conveyed to the mixer, completing the batch cycle. Twelve batch cycles can be performed per hour.

An interesting solution also for other industries

This design of the automated dosing and weighing system is not only revolutionary for the animal feed industry, but also for many others that use small components with diverse characteristics.

This solution has potential for every company where raw materials are dosed and weighed with utmost accuracy, and hygienic demands require the prevention of contaminations.

Key components

of this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.