An efficient ingredient feeding system for a leading bakery company: With the highest quality and efficiency, it feeds the production process with all ingredients, from wheat flour to liquid yeast.

Description

Handling of small, medium and large components

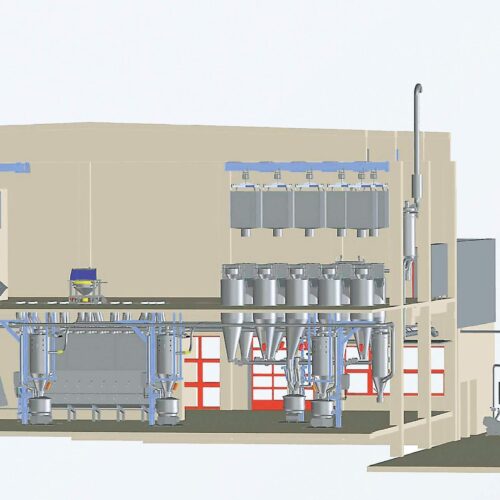

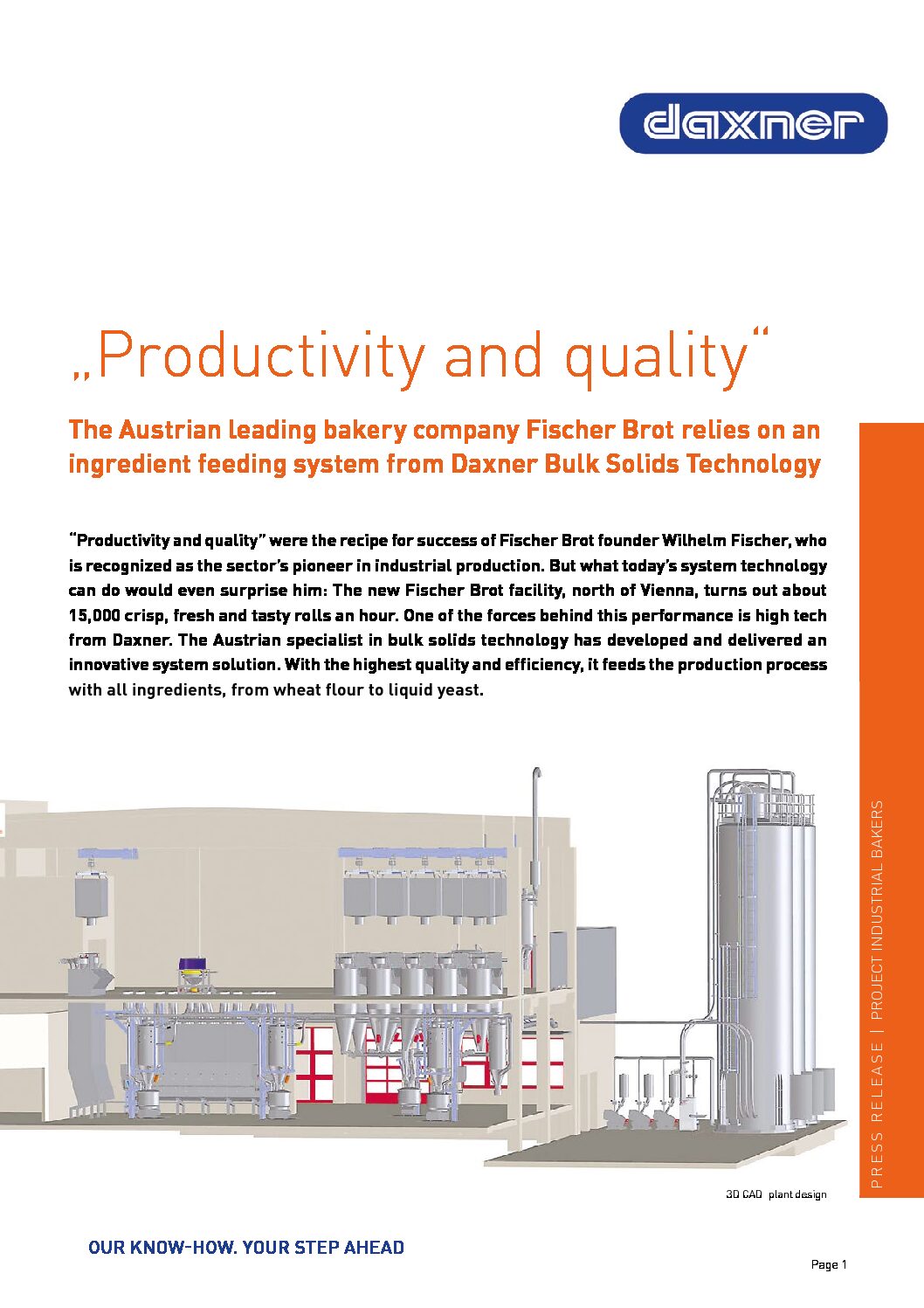

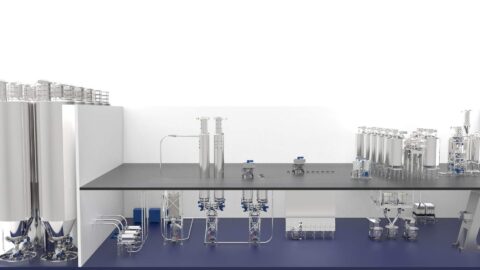

The Daxner system solution feeds all dough ingredients into the production process. They all have different bulk characteristics: The ingredients used come in powder, grain or liquid form and include wheat and rye flour, bread spices, salt and pumpkin seeds, as well as liquid yeast, oil and water. Furthermore the system developers were challenged with the varying quantity requirements, in order to find an efficient, cost-effective solution. Characteristic for the plant is a feeding system divided into four sub-areas tailored to large, medium and small components, as well as liquids. It feeds them into their corresponding batch-dough shell and transports the weighed and dosed ingredients to the kneader.

Fully automated feeding of large and medium components

The main dough ingredients, wheat and rye flour, are stored in three 65-cubic-metre aluminium outdoor silos. A silo head space dehumidifier prevents the formation of condensation. Pneumatic pressure conveys the flour to one of the four weighing bins with integrated filters, where the right quantities for each batch are weighed and dosed into the dough shell. In order to feed the three pneumatic conveyor lines to the weighing bins simultaneously (normally only possible as an option), the cone of each outdoor silo is equipped with its own fluidizing bin discharger. Besides increasing capacity, this technical detail increases system availability quite significantly.

The medium components, which are stored in Big bags, are fed by five Big bag discharge stations. They are stored in intermediate bins and dosed fully automated into the weighing bin or corresponding dough shell.

A manual dosing system for micro components

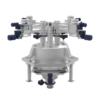

For small and micro components, Daxner has developed a very practical solution that is also efficient and cost-effective. A mobile bag dump station fills a total of 24 micro component cells, while three other cells are fed with Big bags. Using position sensors, the trolley is moved directly onto the small component cell to be loaded and is docked there pneumatically. Filling is performed completely dust free by using an aspiration system.

Dosing is done manually, but completely operator-controlled, guaranteeing a 100 percent traceability. An easy-to-read info terminal guides the operator to each manual component necessary for the batch and stipulates the exact dosage. If the wrong container lid is opened during removal, for example, the process is stopped immediately. The manual components are dosed into an intermediate bin which is positioned for precise weight determination on a mobile, high-resolution platform scale. With all of the precisely dosed and weighed small components, this is transported in sequence to the dough shell.

Proven in practice

The company has been using it for about many years to its complete satisfaction.

Moreover, the system is completely made of stainless steel. It meets not only the highest quality demands, but also the HACCP criteria and IFS standards.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.