Condio, a leading manufacturer of stabilizers and food additives situated in Werder (Havel) in Germany, contracted Daxner with the engineering, fabrication and installation of an innovative plant solution. The expansion of the factory grounds included a new production building, a laboratory and an office. The solution consists of 4 mixing lines with different mixer sizes and a filling station including a control screener.

Description

Raw materials storage

The raw materials are stored in a high-bay storage system. From there they enter the mixing lines. A commissioning station pre-weighs small components and fills them into bags or crates. The commissioned ingredients are set aside at the marked storage areas of the respective production line.

Dosing

According to the recipe at hand, all components are filled into a bag discharge station. A pneumatic conveying line transports the ingredients into weighing bins above the mixers. Optionally, the bag discharge station can be equipped with a control screener.

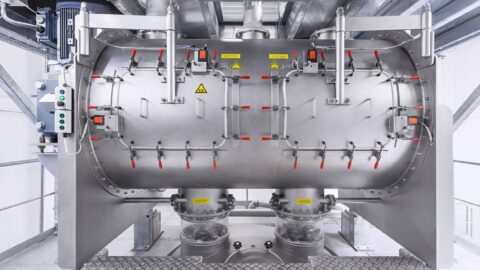

Mixing lines

After all components have arrived in the weighing bin, they are emptied into the mixer situated below to start the blending process. After the mixer blended the ingredients into a homogenous product, the contents are emptied into the Big bag filling station.

A rotary valve transports the product to the screening machine, which sieves the blend efficiently and fractions out any clumped particles. Eventually, the screened product passes through an all-metal separator to filter out any ferrous particles before reaching the Big bag filling station.

The entire plant is equipped with several aspiration systems to minimize the formation of dust.

Key components

of this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.