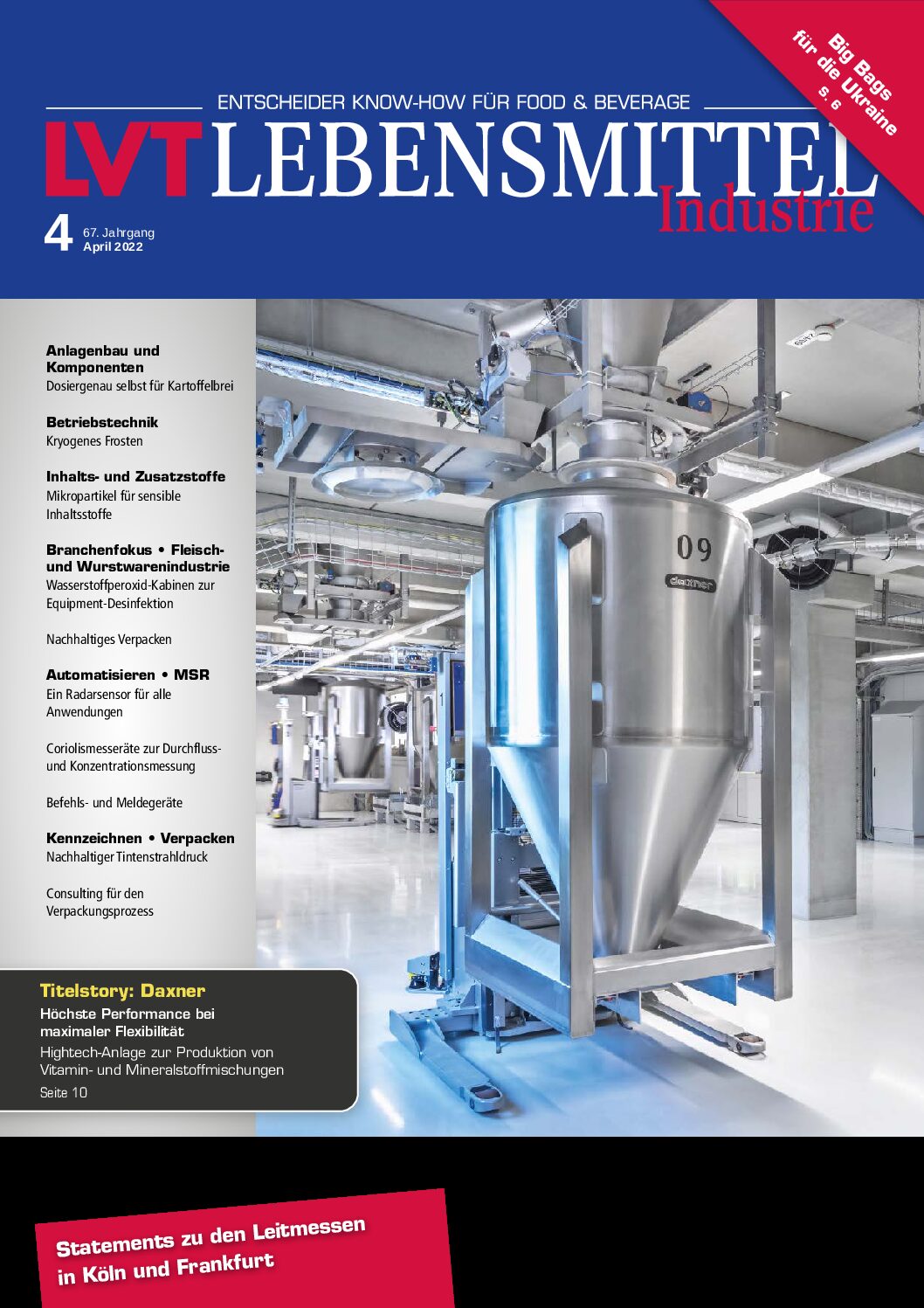

One of the leading companies for animal nutrition & health contracted Daxner with the engineering, fabrication and installation of a fully automated solution for the production of mineral and active ingredients. The plant was implemented into a newly built 3,500sqm large building with a 32m high mixing tower. The 54 storage silos with an automatic dosing system hold up to 1,400 tons of raw material. The whole plant was optimized for easy cleaning, hygienic design and to avoid cross-contamination. Weighing units dose the components before an automated guided vehicle (AGV) transports them to the container lift.

Description

Raw material/Storage

The raw materials can be divided into major, medium, small, micro and manual components. Major components arrive in tanker trucks and are stored in large storage silos. The filling happens pneumatically; all raw materials go through a sieve and magnet to filter out any impurities.

Medium, small and micro components are stored in day bins of various sizes. Fully automated Forklifts, pallet conveyors and pallet lifts transport the pallets and Big bags from the high bay storage unit to the different stories of the storage silos.

The contents of Big bags, bags and containers (premix) are filled into the day bins. Mobile bag, Big bag and container discharge stations dock onto to the respective day silos. Once again, the raw material is control screened to prevent impurities. The mobile stations offer easy clean functions to avoid cross-contamination with minimal effort and maintenance downtime. Since the various raw ingredients have to meet different quality requirements, the sieves can easily exchanged within a few seconds.

Manual components, which are only required in very small doses, are filled in boxes in a separate commissioning station. These boxes are stored in a shelf system.

Dosing

According to the recipe at hand, weighing units dose all automatic components, setting them aside for pick-up. Manual components are commissioned into boxes (Pick to light system) and/or are transported as batch bags to the manual intake station.

Container transport system DCS

The laser controlled, driverless container system collects the dosed raw materials from the weighing unit and the manual intake station and transport them to the container lift. With the help of the container lift and roller conveyor, containers are positioned above the mixer and emptied automatically.

On the different levels of the production facility, laser controlled, automated guided vehicles (AGV) harmonize perfectly with the fully automated Daxner container handling system DSC to collect the valuable raw materials. Hand pallet trucks maneuver the containers on the different floor levels. To transport containers from one level to the next, a container/pallet lift was implemented.

Mixing plant

The containers empty their content into a mixer in the container discharge station. Additionally, during the first mixing phase up to 5 different liquid components can be added automatically. After the mixer blended the ingredients into a homogenous product, the product gets discharged into a mixer under hopper.

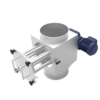

A rotary valve moves the product to a centrifugal screening machine for intense control screening, fractioning and de-agglomeration of unwanted lumps. Finally, the sieved product goes through a pipe magnet to separate any ferrous metal parts and lands in one of the three buffer tanks before reaching the Big bag and bag filling station.

The complete production plant is equipped with several aspiration systems to minimize dust.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.