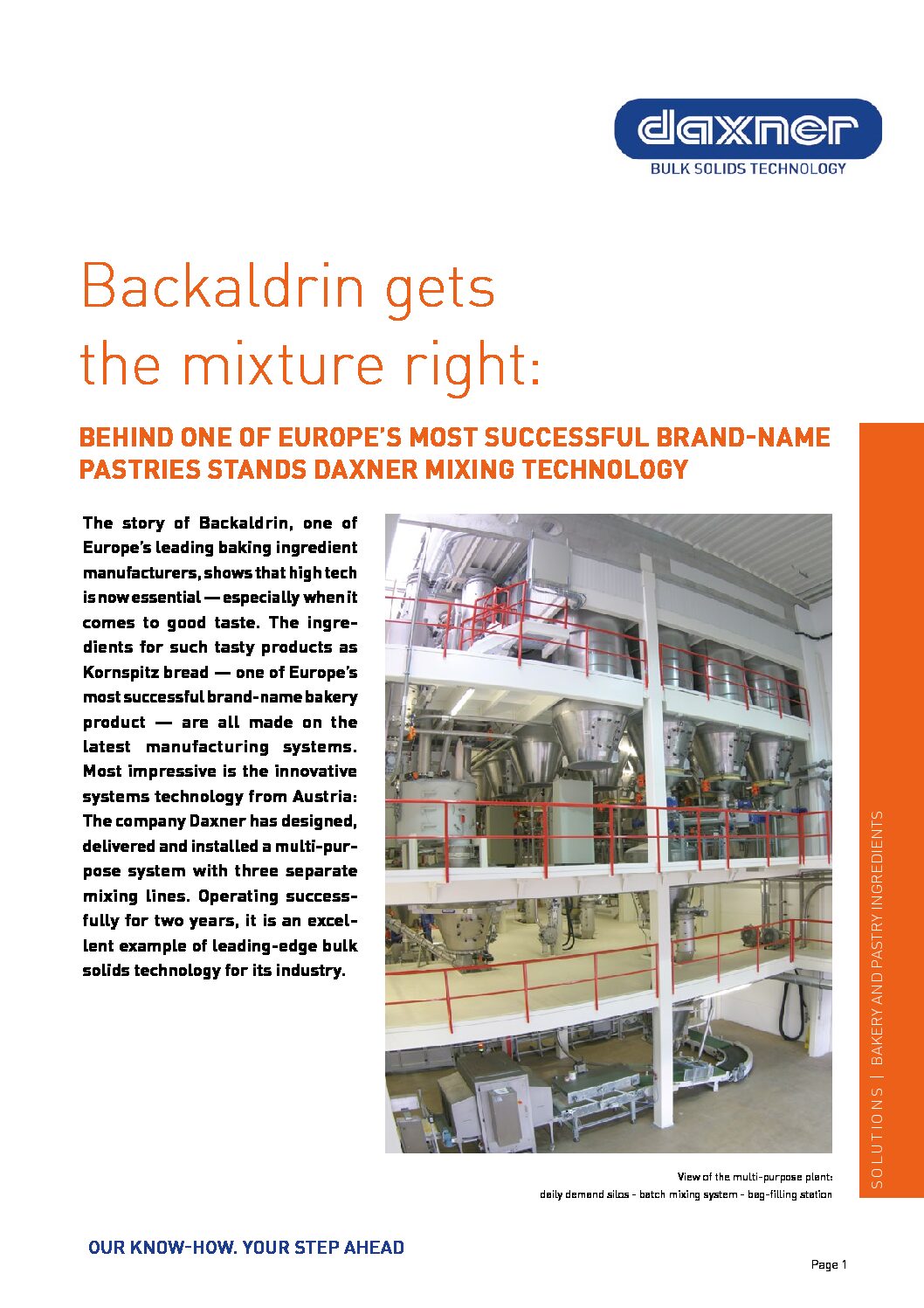

As an investment in the company’s future, the innovative baking ingredient manufacturer set its eye on expanding its existing capacity and ensuring its technological advantage. Daxner convinced with an innovative, sustainable solution: A multi-purpose system with three separate mixing lines. For two years now, it has proven itself to the customer’s complete satisfaction.

Description

With the multi-purpose system Daxner developed a complete solution that ensures top-quality products along with great production flexibility and economy. Based on a CAD system design, about 2,000 hours of planning resulted in a system that automates the entire production process, including storage and discharging, dosing and weighing, feeding and mixing, all the way to packaging. Due to the comprehensiveness of the task, and the dimensions of the project, the development process involved specialists from other fields from the very beginning. These included control and electrical technology, steel construction and mixing and filling technology.

Meeting the highest demands

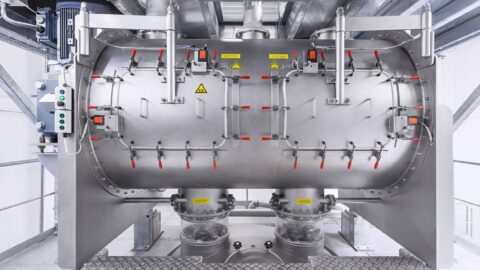

It incorporates not only product safety, but also traceability of raw materials and batches — plus, it is very easy to clean. Equally important to its performance are gentle material and product handling with pneumatic conveyor technology, conditioned conveyor air, and the technology used for the mixing process. High-precision mixing and simultaneously gentle product handling are achieved with the vertical two-shaft mixer. The plant complies to the highest standards , such as ISO-9000, HAACP and IFS.

One system, a multitude of products

As a multi-purpose system, it consists of three mixing lines that allow a single production system to produce a wide range of products, such as convenience mixes, fine baked goods and fillings.

This poses another challenge in the wide diversity of raw materials used: From very sticky to shooting, heavily fluidizing bulk materials, there is a wide range of varied characteristics that complicate handling.

From raw materials to finished baking ingredients

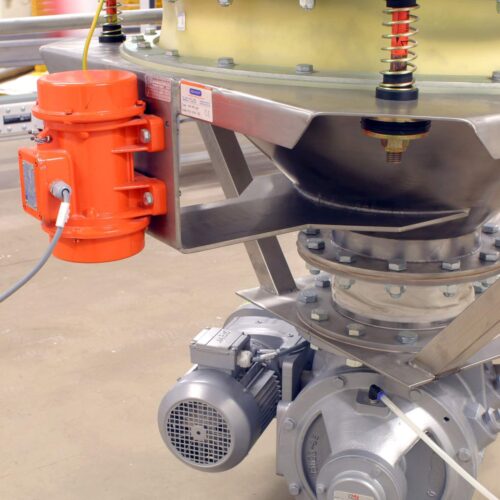

The raw materials for the final products are stored in external silos. Pneumatic conveying brings a wide array of components into the day silos, including wheat meal, spelt flour, rye meal and granulated sugar. All silos and all containers have weighing equipment that continuously monitors the filling level. The 32 silos have capacities up to 12 m3 and can also be manually loaded with bags by a total of three bag dump stations with control screens. Vibro bin dischargers handle the discharge of the products. Dosing screw conveyors move the product to the weighing bin. For both high-volume and very precise dosing, separate coarse and fine dosing screws are used.

The weighing of raw materials takes place in weighing bins, from where the product is brought to the respective, preliminary mixing bin of the three separate 2,500-litre batch mixers. In front of each batch mixer there is a bag intake station with weighing equipment to feed minor bagged ingredients. After successful mixing, the finished products reach the post mixing bins. For fatty baking ingredients, rotary bin dischargers are used. The finished products are stored in an automatic pallet storage and retrieval system.

Sophisticated quality assurance

All raw materials pass a control screen and are also checked for metallic impurities. The finished products even undergo double inspection: Metal detectors find and remove all foreign metal objects. Moreover, the system uses an X-ray device that is an innovation in the foods industry: Before the baking ingredients leave production, they are X-rayed, so that all foreign objects can be reliably seen and removed.

Cleanliness through a central dust extraction system

Another intelligent detail is the central dust extraction system that has proven itself with distinction. A pipe system provides a connection to each production station. Product residues are extracted by a cyclone filter. The dust extraction system is designed for simultaneous operation of six extraction points with 2-level vacuum pumps.

Key components

for this solution

Sounds interesting?

Let us get know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.