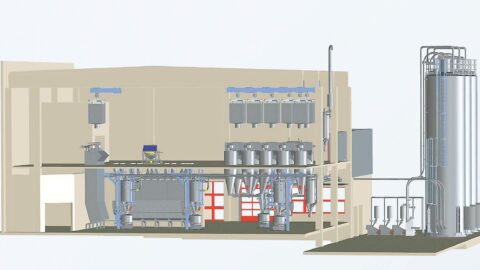

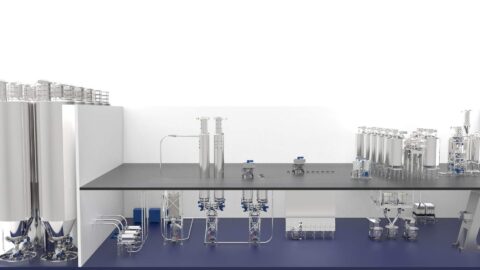

A renowned producer of baked goods and long-term customer of Daxner extended its successful production facility in Upper Austria. Besides 5 new outdoor silos, the plant was upgraded to 4 production lines.

Description

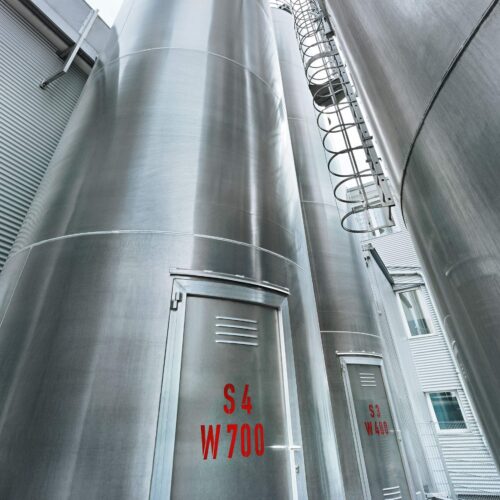

Silos

Firstly, the flour arrives in tanker trucks. Pneumatic pressure conveys it into the designated outdoor silo.

An aeriation system mixes and loosens up the flour in the silo funnel. This way, the flour can easily be transported out of the silo into the screening station. Two pressure blowers located in a room next to the outdoor silos enable the pneumatic conveying of the product.

Raw material intake and conveying

2 centrifugal screeners screen the flour to dispose of any unwanted coarse product. The fine product continues on to either production line 4, the day silo for rye flour or the weighing bin for the wheat sour dough.

There, the wheat flour is weighed before a screw mechanically conveys it to the kneader. If needed, dusting flour can be extracted at the screw’s outlet.

Baking aids and salt enter the production process via Big bags or bags that are emptied at the bag intake station. Some of the ingredients continue directly to the weighing bin before reaching the kneader. Moreover, liquid yeast and oil are added from the on-site liquids station on production line 4.

The medium components station in line 4 consists of several Big bag discharge stations with conveyor screws. The ingredients are sieved through the built-in screen of the bag intake station before a screw conveys the material to a weighing bin.

A double screw transports salt and the rye flour from the day bin to the weighing bin. The sieved flour from the centrifugal screener is stored in the day bin for rye or before entering the weighing bin.

The dusty air is cleaned by an aspiration filter The cleaned air exhausted back into the facility.

Soaker system

The soaker system consists of a Big bag discharge station, day bins, a weighing bin and a conveyor screw. This is where linseeds, oats, sunflower seeds and malt flour are conveyed pneumatically from the Big bags into the day bins.

The Big bag outlet is connected to the Big bag discharge system where the medium components enter the bag intake station to be sieved by the control screening machine. Afterwards, a diverter valve conveys the bulk solids into the respective day bin. According to the recipe at hand, the medium components are transported via vibro bin dischargers to the screws. Next, a screw conveyor transports the weighed product to the soaker mixing bin.

The water supply comes from a water mixer containing tap water, hot water or ice water.

Wheat sour dough system

The water mixing system supplies the wheat sour dough blender with water. The scale of the mixing container serves as control weighing unit.

Flour from the outdoor silos reaches the weighing bin positioned above the mixing container via a pneumatic conveying line. A rotary valve and a piping system transport the goods from the weighing bin to the mixing container.

The homogenous blend continues to the storage tank via a pump. The sourdough starter is added over a separate insulated and cooled preparation tank.

Metal detection system

The metal detection system is located shortly before the packing station. The finished baked goods passes through the system on a conveyor belt to detect any ferrous parts.

Key components

of this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.