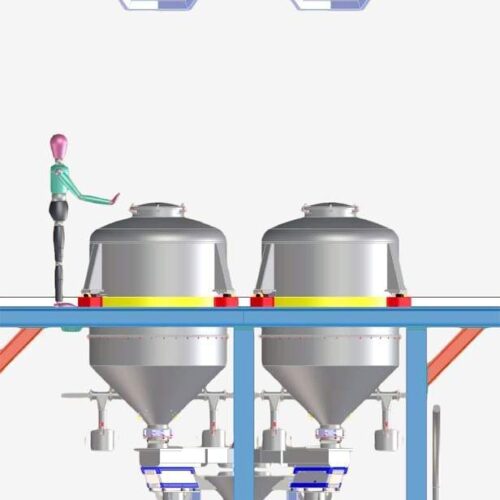

Silo plant with Big bag discharge system for the production of chocolate

Daxner delivered a silo plant with a big bag discharge station for a prestigious chocolate manufacturer.

Description

Various raw materials such as hazelnuts, almonds etc., which are delivered in big bags, are loaded into a collecting hopper by daily bins, from there these ingredients are added to further processing.

The daily bins have a net volume of minimum one big bag and are designed as weighing bins. The required amount is dosed by loss in weight.

Bulk density of the components: 500 kg/m³

The product is dosed out of silos (loss in weight):

- Dosing accuracy ranges from +/- 2 kg

- Digit of the dosing is +/- 1 kg

- A vibro dosing channel doses the product out of daily silos

- The capacity is appr. 3.000 kg/h

Separate batches are dosed contamination-free, since the blending of ingredients is not requested.

Big bags are wrapped and delivered with vacuum packaging. Before being filled into the daily bins the packaging will be removed.

The daily bin is selected by a barcode hand scanner. The target weight is adjusted manually. Touch panels are installed in both levels of the production facility.

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.